Tripropylene Glycol: An In-Depth Look

Historical Development

Tripropylene glycol first made its presence known in the early twentieth century. Companies looked for new chemicals to help the booming industrial sectors. Chemists were already finding value in glycols for their unique blend of viscosity and solubility, and curiosity around oligomers pushed the focus towards higher glycols like tripropylene glycol. Over time, it became clear that tripropylene glycol suited a range of processes, from textiles and paints to plastics and functional fluids, setting the tone for its continued industrial use. Its historical footprint serves as a case in point of how industrial demand shapes chemical innovation, and it’s no surprise that the growth of the plastics and resin industry pulled this compound into greater use. I have seen small factories treat it like a workhorse, especially when nothing else fits precise viscosity and solvent needs.

Product Overview

Tripropylene glycol comes as a clear, nearly odorless liquid. Manufacturers lean on it because it bridges the gap between lighter glycols, like monopropylene glycol, and heavier ones, bringing a mid-level viscosity and solid solubility with water or organic solvents. This makes it more than just a base chemical—it's a building block for performance in many products, from cosmetics to industrial oils. Folks who run production lines have always told me that its reliability reduces downtime and lets them fine-tune formulations. Whether you’re working with flexible plastics, personal care items, or hydraulic fluids, you’ll find tripropylene glycol making formulations easier to reach target performance.

Physical & Chemical Properties

This compound shows off a boiling point near 280°C and a melting point hovering deep below freezing. Density sits slightly over one gram per cubic centimeter, and it easily dissolves in water and organic phases. Its moderate vapor pressure means it rarely evaporates off at room temperature, a reason why facilities running open systems don’t worry much about losses. That balance in physical properties gives it a stable shelf life, so handling and storage rarely call for anything but basic care. Chemically, it holds up during processing—ethers and esters formed from it remain stable even if processing temperatures climb. Its three propylene oxide units give it versatility, letting manufacturers blend or chemically tweak it as needed.

Technical Specifications & Labeling

Buyers ask for technical specs that guarantee consistent supply and predictable results. Quality certificates list purity—often above 98%—and trace impurities such as water, mono- and dipropylene glycols. Labeling covers CAS number, UN code for shipping, and clear information about storage conditions. Signal words like “Caution” or “Warning” come printed on containers due to skin and eye irritation risks. Standard containers range from 200L drums to bulk tankers, with each label showing batch numbers and manufacturing dates. Such precise records go a long way: they keep supply chains transparent and help users backtrack any quality or safety concerns. Consistency starts with clear labeling, and in my view, sloppy record-keeping leads to headaches nobody wants.

Preparation Method

Industries produce tripropylene glycol by hydrating propylene oxide using catalysts that shift the product balance toward tri- and higher glycols. This batch or continuous process keeps tight control on temperature and pressure, as runaway reactions either chew up more feedstock or skew the product to unwanted oligomers. Operators monitor parameters to ensure conversion goes to the right chain length, while separations technologies strip off mono- and di-propylene glycol, sending the right fraction for purification. Most plants I’ve toured run these reactions with strict attention because even slight missteps turn into rework or lost yield. The art stands in blending chemical know-how with mechanical control—turning base chemical building blocks into reliable industrial inputs.

Chemical Reactions & Modifications

End-users want versatility, and tripropylene glycol accommodates. Reacting with acids forms esters, which turn up in lubricants and specialty fluids. Dehydration gives cyclic ethers, found in fuel additives. The glycol’s multiple hydroxyl groups enable cross-linking or chain extension, letting it build polymers or modify resins. In the lab and the factory, this means chemists count on it when aiming for flexibility in molecular design. Its backbone stands up well to alkalis or most acids, avoiding the reactivity headaches found with lighter or heavier polyols. Turn it into ethers or use it to plasticize—every modification delivers properties that basic glycols can't easily match.

Synonyms & Product Names

Depending on supplier or market, this compound appears under names like TPG, 1,1′,1″-Tri(propan-2-ol), or even “trimers of propylene glycol.” Large providers stamp their names on shipping labels, while specialty chemical firms add branded codes for particular purities or blends. These synonyms can trip up procurement if a purchasing agent isn’t careful, but industry catalogs tend to list CAS numbers to cut confusion. Most production managers tell me that as long as the paperwork matches the analysis, the name on the drum matters less than the specs inside it.

Safety & Operational Standards

No chemical arrives without risks, and tripropylene glycol sits squarely in the safe-but-cautious camp. Skin contact can irritate. Spills produce slippery floors, and inhaling mist serves up respiratory discomfort. Safety Data Sheets stress gloves, goggles, and good ventilation. Operators must treat drum handling, transfer pumps, and cleanup like any industrial operation—sloppy habits only lead to accidents. Storage guidelines point to cool, dry places with ventilation that clears vapors and smooths heat buildup. Emergency plans include eyewashes, chemical spill kits, and blocking off drains in case of leaks. Nobody wants to cut corners on safety, because even a “mild” chemical can cause real headaches if respect goes out the window.

Application Area

Industrial and consumer sectors draw from tripropylene glycol’s diverse toolkit. Polyurethane foams and flexible plastics depend on its backbone to drive elasticity and resilience. Cosmetic and personal care formulas use it for consistent texture and solvency, while fragrance mixers value its low odor. Coolants, de-icing fluids, and lubricants all pull performance from the compound’s thermal stability and miscibility profile. Textile mills use it in fiber treatments, paint factories rely on it for flow control, and resin manufacturing taps it for tailored properties. Even specialty inks and agricultural adjuvants draw on its chemical compatibility. Every corner of production feels its reach: behind the scenes in pipelines, up front in consumer goods.

Research & Development

Tripropylene glycol’s role in R&D stretches well beyond simple choices about purity or cost. Chemists dig into modifying its structure for biodegradable esters, targeting greener plastics and new surfactants. Engineering circles look at performance additives for synthetic fluids, with tripropylene glycol forming a part of innovation stacks for heat transfer and electrical stability. Recent years brought focus to reducing environmental impact, so research shifted to renewable feedstocks or catalysts with lower toxic footprints. These R&D pushes excite real-world users, who see a route to new markets and eco-certifications. Time spent in industrial labs testing blends for solubility, volatility, and long-term performance helps shave down costs and turn new formulations into scalable products. In my own experience, spending extra hours on blend optimization often leads to real breakthroughs in quality and margin.

Toxicity Research

Extensive toxicity studies show tripropylene glycol carries low acute toxicity for humans and the environment, but this doesn’t give free rein for careless use. Repeated skin contact causes irritation, and animal studies flag concerns at extremely high exposures. Disposal into water systems draws scrutiny since breakdown in aquatic settings depends on oxygen and bacteria that don’t always keep up. Most regulatory agencies stipulate maximum exposure levels in work environments, demanding proper training for handlers. Toxicology labs chase down metabolites, hoping to catch any long-term risks before they spread into the workplace or environment. Questions remain about chronic exposure, so research continues, backed by funding that recognizes how important safety really is to chemical supply chains.

Future Prospects

Tripropylene glycol sits on the edge of future challenges and opportunities. Demand rises for materials that cut carbon footprints, so producers look at bio-based synthesis routes and ways to upcycle waste glycols. Technical teams target new blends for electric vehicle coolant and next-generation resins. Regulatory agencies push for transparency and tighter controls, nudging manufacturers to document impacts from cradle to grave. Innovation may push this compound into additive manufacturing or bioplastics, if R&D finds the tweaks that balance performance against cost and sustainability. As industries keep evolving, those investing time in understanding supply risk, technical opportunities, and market trends stand to benefit most. Watching the chemical sector chase cleaner, smarter, and more versatile compounds, I see tripropylene glycol holding firm as a touchstone for balanced performance and reliable manufacturing solutions.

From Industrial Workhorses to Home Products

Tripropylene glycol doesn't get much attention outside certain industries, but it turns up in more places than most people realize. It belongs to the glycol family, known for their moisture-holding ability and mild taste, but tripropylene glycol stands apart because of its low odor and versatility. Factories all over use it to keep machine parts moving, mix it into cleaners and detergents, and rely on it for safe, effective formulations. It offers just the right mix of properties for these tasks—high boiling point, ability to dissolve oils and greases, and a reassuring record for safety when handled properly.

The Backbone of Cleaner and Safer Products

Anyone who has ever scrubbed down a kitchen or bathroom, worked on an engine, or even just enjoyed fragrant air fresheners has run across tripropylene glycol’s hidden handiwork. It acts as a carrier in air fresheners, letting scents evaporate slowly into the air. Its ability to grab onto water makes it great in cleaners and degreasers. It breaks up tough soils without harshness, and balances heavy-duty performance with safety—companies don’t have to load their products up with harsh chemicals. The U.S. Food and Drug Administration lists it as Generally Recognized as Safe (GRAS) when used as a food additive or in indirect contact with food, underscoring its long track record.

Essential in Coatings and Lubricants

Tripropylene glycol finds regular use in paint shops and workshops alike. It helps paint spread evenly, extends drying time just enough for touch-ups, and keeps colors looking sharp. Folks who work with coatings count on it to help formulas resist streaking and clumping. Meanwhile, automotive shops and factories trust it as a base for brake fluids and lubricants, especially for systems that can’t risk solvents breaking down gaskets or seals. It plays its role behind the scenes, not making a big deal, but essential just the same.

The Safety Perspective

Safety always matters most with chemicals, and tripropylene glycol offers some peace of mind. Unlike its cousin ethylene glycol, which can be toxic, tripropylene glycol carries a much lower risk. Most safety data sheets describe it as having low acute toxicity. Workers still use gloves and good ventilation, but large-scale issues are rare when it’s stored and used as directed. Because it’s in so many products that come into homes and contact skin, companies build their processes to avoid spills and monitor exposure carefully.

Finding Balance with Environmental Impact

Tripropylene glycol is less likely than many solvents to end up polluting the air or water. It breaks down in the environment within a few weeks. Still, as factories and labs look for greener options, there’s a constant drive to recycle solvents, capture runoff, and test safer blends. Some manufacturers now focus on reclaiming glycols after use, putting circular processes in place instead of treating everything as disposable.

Looking Ahead

The search for safer chemicals rests on experience, data, and honest effort from both industry and regulators. Some see tripropylene glycol as a model for balancing performance with a solid safety profile. If more companies choose careful sourcing, smart recycling, and clear labeling, it can keep proving its worth. As science digs up better and safer ways of doing things, tripropylene glycol may hold onto its position or inspire even more effective solutions. It’s a reminder that the ingredients nobody sees often carry the load in making everyday life work a little easier and a little safer.

Understanding Tripropylene Glycol

Tripropylene Glycol shows up in plenty of products spread across different shelves. You’ll find it in skin creams, deodorants, perfumes, makeup, and even some industrial fluids. Most folks don’t give its presence a second thought because you rarely see big headlines about it. That doesn’t mean it deserves a free pass. Any chemical that ends up on your skin should come under honest scrutiny, partly because the skin is more than just a barrier—it's a living organ taking on plenty of exposure every single day.

What the Science Says

I’ve looked through dermatologist guidance, safety data, and regulatory discussions. Tripropylene Glycol shares a family tree with Propylene Glycol, which scientists have studied a lot. Regulatory agencies in the United States, Canada, and Europe have reviewed this chemical for years. The U.S. Food and Drug Administration recognizes the use of several glycols in cosmetics at low concentrations as generally safe. European regulators limit concentrations in personal care products, showing that sticking within boundaries is considered important.

Most research suggests Tripropylene Glycol offers low skin toxicity. The Environmental Working Group gives it a low hazard rating for personal care uses. Reports of irritation or allergic reactions are rare and usually limited to people with sensitive skin or those exposed to undiluted or higher concentrations.

On the job as a writer covering consumer topics, I’ve had the chance to talk to formulators and chemists who mix this stuff into cosmetics. Their feedback lines up with published studies: in the right doses, consumers don’t tend to feel any ill effects. In my own home, skin lotions containing glycols haven’t caused visible irritation for my family.

Risks and Responsible Use

Nothing is truly risk-free, and that’s worth recognizing. Undiluted Tripropylene Glycol can cause mild irritation. That’s mostly a concern during industrial handling, not everyday cosmetic application. Some patch tests have shown minor reactions, but most people tolerate it well in finished products. A handful of medical case reports mention contact dermatitis, which is doctor-speak for an itchy rash. The numbers are quite low compared to fragrance allergies or reactions from preservatives.

Reading product labels goes a long way. People with sensitive skin or those with allergies should steer clear of products with questionable ingredients, and consulting a dermatologist always beats guessing. I keep a close eye on new research, and I haven’t seen any evidence prompting regulators to reconsider their safety verdict so far.

Making Safe Choices

Life comes with a balance between convenience and caution. Tripropylene Glycol sits in lots of products because it helps dissolve ingredients, keeps things moist, and feels nice on the skin. For the average person using modern personal care products, it doesn’t pose a major risk. Responsible companies stick to proven concentrations and keep up with regulatory changes. Consumers also play a part: patch test new products, seek medical guidance for existing conditions, and report any bad reactions. Greater transparency is always a win. If makers and watchdogs keep working together, these chemicals stay better understood so people have fewer worries about what touches their skin.

Looking Beyond Just Numbers—Why Chemical Formulas Matter

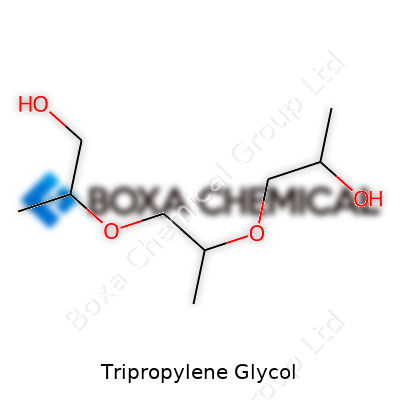

Every bottle in a laboratory cabinet has a secret: the set of atoms it’s made from says a lot about what it can do. Tripropylene glycol’s formula—C9H20O4—seems plain on the surface. There’s power in that string of letters and numbers, though. Many folks recognize this substance by its trade applications and faint, sweet scent, but understanding its formula shows how it behaves across industries, from paints to deodorants.

Peeling Back the Science: What Those Letters Stand For

C9 means you have nine carbon atoms to anchor the structure. H20 means you get twenty hydrogens—plenty to fill out the molecular “branches,” which impacts the boiling point and ability to mix with other solvents. O4 signals four oxygen atoms; those bond into three ether links, forming the propylene glycol “chains.” Each element lines up in a pattern that influences tripropylene glycol’s ability to dissolve other chemicals and resist evaporation. Folks in labs know—combine those, and you have a compound that can handle both water and oils.

Bringing Chemistry to Life—Practical Stakes

I remember working in a research setting that stored drums labeled with complicated names and numbers. Tripropylene glycol was never just a number. Its formula suggested how it would behave. The structure gave it low skin irritation risk, a real blessing for products meant to touch skin. The extra oxygens made it absorb and retain water, so it stopped things from drying out—handy for people formulating cosmetics or antifreeze.

People involved in manufacturing keep an eye on the numbers for another important reason. The backbone of tripropylene glycol allows it to stay stable, even when heated. When making paints or print ink, you want a chemical that resists breaking down early, doesn’t let off dangerous fumes, and stays where it should during curing. That’s why places using tripropylene glycol for industrial coatings, lubricants, or textile treatment care about the exact number of each atom. Even small changes in the formula shift how a blend performs.

Learning from the Past—Handling Chemicals Safely

It’s easy to gloss over, but knowing a chemical’s formula helps avoid workplace surprises. The handful of extra carbons and oxygens in tripropylene glycol means it won’t evaporate easily, so it lingers in open air less than similar compounds. That trait lowers flammability and keeps air quality better for folks working nearby. With the wrong glycol, you end up with more headaches—literally and figuratively.

Responsible Use—The Right Approach Matters

Producers and users face pressure to keep things sustainable and safe. With tripropylene glycol, double-checking the formula matters. Some blends get mixed incorrectly or cut with cheaper alternatives, all in the name of saving money. That usually backfires, leading to ruined products and more environmental waste. Knowing C9H20O4 is not just a trivia fact—it directs safe handling, checks for purity, and hammers home the need for careful sourcing.

Moving Forward—Science at Work

New applications still surface every year. For example, eco-friendly plastics draw from glycols like this. The chemical structure, proven through and through, gives authorities and companies a clear reference for both regulation and innovation. Facts at the molecular level shape smart decisions for health and efficiency. All that from a formula on a label—simple, but far from trivial.

Why Storage Isn’t Just About Shelf Space

Tripropylene glycol doesn’t spark much attention compared to more dramatic chemicals, but asking anyone who’s worked with industrial chemicals, storing it right really matters. Ignoring safe storage turns reliable materials into hidden hazards. This isn’t abstract policy talk—this is about protecting health and property. My background in facilities management taught some hard lessons. I’ve seen lunchroom chatter turn to panic when a storage slip-up fouls the air with mystery odors.

Understanding the Chemical’s Behavior

Tripropylene glycol is a colorless, syrupy liquid, widely used in cosmetics, polymers, and as a carrier for fragrances. It doesn’t burn easily, but that doesn’t mean fire isn’t a concern. Too much heat spells trouble. Unsealed drums can allow trips to the emergency eyewash station. Vapors may not always irritate right away, but keep them contained and they’re bound to sneak up on anyone not paying attention. While it isn't the wildest substance in the cabinet, its quirks give trouble for people who treat it like just another drum on the floor.

Building a Better Storage Area

Don’t tuck tripropylene glycol anyhow near heat, flame, or open sunlight. Out in the real world, someone always pushes for “just put it next to the door, we use it a lot.” That shortcut gives headaches down the road. Fire codes—and insurance adjusters—don’t look kindly on shortcuts. Get it into a cool, dry, and well-ventilated space. I’ve watched companies set up fans thinking they’re keeping it safe. Moving air helps, but it’s better to pick a spot out of strong sunlight or near machinery radiating heat.

Truly tight chemical storage plans treat leaks as all but guaranteed. Place curbing or spill containment palettes under drums and tanks. If a drum does fail, catching a spill saves workers time and the company’s skin. Safety sheets say the same thing, but in practice, more spills get ignored than get reported. Put up those warning signs, change them when they fade, and run drills so folks know what to do if something soaks their shoes.

Physical Security and Maintenance

Physical barriers make a difference. A padlocked enclosure or fenced area keeps out kids, curious staff, or even the stray contractor not reading labels. Regular checks stop routine from sliding into neglect. I’ve seen storage rooms fall into chaos just because no one checked; drums stacked three high, leaking pumps, exit routes clogged. Bring maintenance teams into the loop and encourage reporting, even if it means extra paperwork.

Training Beats Signage

Labels help, but people tend to tune them out over time. Walk through safe handling with new hires and test them once in a while. People remember real experiences, not just what’s written on a poster. Get someone who actually handles drums to demo the best practices. Revisit policies after incidents—even near-misses. Any time product goes missing or you smell something odd, treat it as an urgent meeting point for retraining.

Industry Trust Grows With Transparent Practices

Clients, regulators, and visitors judge any business that touches chemicals by how storage areas look and run. A clean, labeled, and organized zone builds trust. Accidents—the kind tripropylene glycol can contribute to if mishandled—ruin reputations overnight. It’s far cheaper and safer to get storage practices right than to fight fires with damage control after things go wrong.

Understanding What Tripropylene Glycol Is

Tripropylene glycol has turned up across a range of industries, finding work in cosmetics, cleaners, lubricants, and even fragrance products. Folks use it for many reasons, mostly because it holds onto moisture and dissolves other substances. But most people haven’t heard its name, much less thought about what happens if it ends up where it shouldn’t, like in your mouth or lungs.

How Toxic is Tripropylene Glycol?

Through years in research settings and regulatory assessment, scientists and doctors have found that tripropylene glycol carries a lower toxicity compared to other types of glycols. Swallowing small traces will seldom cause big trouble. The European Chemicals Agency marks it as practically non-toxic by ingestion. The U.S. Environmental Protection Agency also lists it in the “low concern” category. At high enough doses, trips to the hospital happen, but that requires ingesting much more than most people ever would by accident. Nausea, an upset stomach, or mild irritation show up first, and you’d have to swallow a fair bit—far more than you'd find by accidentally licking your hands after using a household cleaner.

Risks from Breathing In

Much of the fear around chemicals centers on inhalation. Lab studies on tripropylene glycol vapor and mist give reasons to be cautious but not panicked. Short-term exposure likely causes little harm aside from possible mild throat irritation or a cough if you’re in a badly ventilated area with lots of vapor in the air. Workers who deal with concentrated forms daily use masks as a rule because constant exposure sometimes triggers headaches or dizziness. It’s still a far cry from chemicals like formaldehyde or ammonia that punish lungs in seconds.

Learning from Past Chemical Scares

History shows why people worry about substances they can’t easily pronounce. Chemical accidents in homes have happened with things as common as antifreeze (ethylene glycol) or household bleach. Those chemicals, unlike tripropylene glycol, have much higher toxicity. Tripropylene glycol’s neighbors (propylene glycol and dipropylene glycol) land in medicines and even processed foods. Yet, calls to poison control rarely involve tripropylene glycol. I have fielded these calls myself, and most end with reassurance, a glass of water, and no trip to the emergency room.

Reducing Real-World Risk

No one plans to drink or inhale chemicals meant for cleaning or industrial work. Still, good habits keep problems off the horizon. Always read labels—don’t let curious pets or kids near products with names that sound out of place in the kitchen. Ventilation matters. Open a window when you use sprays indoors, and don’t mix products unless you know what’s in them. Safety data sheets for tripropylene glycol call for gloves and eyewear for professionals, but household users rarely get that much exposure. Storing all such products out of reach and clearly labeled does more to keep everyone safe than any warning on a data sheet.

Weighing the Real Hazards

Of the chemicals stocked under sinks and in garages, tripropylene glycol doesn’t rank among the worst offenders. Years working in public health have taught me that the greatest threats often come from forgetting the basics—washing hands, reading instructions, and never transferring cleaners into unlabeled bottles. Tripropylene glycol should be handled with care, but it doesn't stir up the levels of worry that other industrial chemicals do. Transparency from manufacturers, regular review of toxicity data, and following safety instructions close the gap between risk and reality.