Trichloroethylene: Past, Present, and Future

Historical Development

Trichloroethylene first appeared in the labs of the 19th century. Chemists of that era saw its promise as a solvent and seized the chance to swap it in for older, more dangerous compounds. Surgeons and industry operators bought into trichloroethylene early as an anesthetic and degreasing agent, believing it cleaner and safer than what came before. Over the decades, its popularity grew in factories, dry cleaning shops, and even household products. By the mid-20th century, few workplaces or hospitals were untouched by it. But as scientists tracked worker health more closely, studies found links between long-term exposure and serious diseases, including cancer, liver damage, and reproductive problems. These findings turned public opinion. Governments started writing rules to limit its use, and research began to dig deeper into alternatives.

Product Overview

Trichloroethylene is colorless and smells sweet, though that odor can fool you—it signals danger at much too high a concentration. Traditionally sold as a liquid, it quickly vaporizes at room temperature. Its claim to fame grew out of its ability to dissolve greases, oils, waxes, and tars with remarkable speed. For generations, factories used it to clean metal parts on assembly lines, breathing new life into equipment, engines, and all things mechanical. Its stubborn grip on contaminants brought jobs to city centers and reshaped commercial dry cleaning. Even so, widespread contact has forced many to rethink dependency, especially with better technology taking over its usual roles.

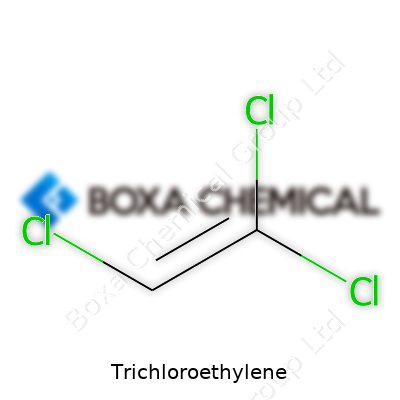

Physical & Chemical Properties

This solvent boils at about 87°C, meaning it doesn’t stick around in warm places. Its density puts it well above water’s—at nearly 1.46 g/cm³, it sinks quickly when spilled. The molecule itself, C2HCl3, packs three chlorine atoms, which make it heavier and less likely to catch fire, though not non-flammable. Unsurprisingly, chlorine’s involvement means trichloroethylene does not mix well with water, preferring oils or other organic solvents. Its high volatility makes air-dispersal a constant risk in poorly ventilated spaces, which matters for anyone breathing the air nearby.

Technical Specifications & Labeling

Suppliers stamp containers with warnings, noting flammability, toxicity, and handling recommendations. Labels carry the UN number 1710 and the hazard pictograms – a skull and crossbones for acute toxicity, a health hazard for long-term effects, and an exclamation mark for skin and eye irritation. Purity hovers around 99.5% for industrial use, but residue limits for water, stabilizers, and acid acceptance all show up in paperwork. Storage needs tight seals, a cool spot, and chemical-resistant containers. These days, labeling can't get away with half-truths—workers, safety managers, and regulators expect the facts straight.

Preparation Method

Manufacturers usually produce trichloroethylene from either acetylene or ethylene. The old-school process took acetylene and shot it full of chlorine, often using carbon catalysts. Newer methods use ethylene, where the gas soaks up chlorine in the presence of catalysts to form trichloroethane, which then loses hydrogen to become trichloroethylene. Chemical firms keep their methods fine-tuned to squeeze out as much product with as little waste as possible. Regardless of the route, chlorine handling and thorough venting remain critical—a lesson written in every safety manual after decades of industrial accidents.

Chemical Reactions & Modifications

Although stable under ordinary storage conditions, trichloroethylene turns dangerous when it meets strong bases or metals like sodium, potassium, or aluminum, particularly under heat. These combinations can set off violent reactions, with toxic byproducts such as phosgene and dichloroacetylene forming in the mix. In the environment, trichloroethylene can break down under sunlight or be transformed by soil microbes, but certain reaction products, especially vinyl chloride, also upset regulators and activists because of their toxicity. Chemists also modify trichloroethylene through hydrolysis or hydrogenation to make other chemicals, but these methods remain rare outside specialized research settings.

Synonyms & Product Names

You won’t always see ‘trichloroethylene’ on the label. Many people know it as TCE. Older documents might mention Triclene, Ethin, Tri, or even Trilene. Some technical literature refers to acetylene trichloride. The variety of product names leads to confusion, especially for workers new to old machines or legacy equipment manuals. It becomes vital to double-check chemical identities before any hands-on work.

Safety & Operational Standards

Heavy use in early decades led to overexposure and harsh lessons. Inhalation, skin contact, and even accidental ingestion delivered fast-acting effects—dizziness at low doses and loss of consciousness at high. Most alarming, repeated exposures brought chronic diseases. Agencies like OSHA, NIOSH, and the EPA stepped in with strict occupational limits. Permissible exposures dropped. Modern regulations require fume hoods, airtight storage, regular air monitoring, and personal protective gear. Spill protocols call for immediate evacuation and containment. Simpler times accepted more risk, but now every workplace puts worker health first, knowing how the chemical’s dangers linger long after the smell has faded.

Application Area

Factories have long trusted trichloroethylene for degreasing heavy machinery and cleaning components before assembly. The dry cleaning world owed much of its spotless reputation to its strength and speed. The aviation sector, electronics shops, and auto industries used tons of it on engine blocks, circuit boards, and delicate instrument parts. Medical suppliers once appreciated its anesthetic effects, though few dare try such applications today. As science has highlighted its risks, new uses face an uphill battle for acceptance. Regulations force companies to swap it for safer, often more expensive, alternatives.

Research & Development

Recent research focuses on understanding and countering harmful effects while seeking smart substitutes. Scientists sift through thousands of new molecules in search of chemicals that clean just as well but leave people and the environment unharmed. Environmental engineers push for bioremediation—using certain microbes to transform trichloroethylene in soil and water into harmless compounds. Industrial chemists tune cleaning mixtures and manufacturing methods, hoping to hold on to efficiency without repeating mistakes from the last century. Universities continue tracking human health outcomes with massive studies that span decades, aiming to settle questions about cancer, immune disorders, and more. This research bridges lab lessons and real-world safety with every new paper.

Toxicity Research

The harm this chemical causes has forced generations of scientists to double-check every assumption. Early studies revealed widespread organ damage in people with long-term exposure—especially the liver, kidneys, and nervous system. The International Agency for Research on Cancer moved it onto the list of known human carcinogens several years back, based largely on studies of workers in cleaning and degreasing plants. Children born close to contaminated water sources raised alarms about birth defects and developmental problems. Public outcry pushed governments toward funding larger projects to map exposure routes and track outcomes. Litigation followed in more than one country, drawing attention to remediation and long-term health monitoring.

Future Prospects

The road ahead leads away from TCE. Chronic health effects, stubborn cleanup problems, and high regulatory hurdles put a chokehold on its future in Western markets. Alternatives—ranging from green solvents and water-based systems to advances in robotics cleaning—are popping up everywhere heavy cleaning or degreasing work operates. Emerging economies, wrestling with cost versus safety, still grapple with balancing cheap, strong solvents and lasting public health risks. Innovation in chemical processing, improved workplace automation, and tougher international treaties may finally close the door on trichloroethylene as a staple in cleaning and industrial chemistry. A lesson learned—public health and worker safety carry too much weight to ignore, even for the most effective industrial tool.

The Everyday Chemical in Industrial Shadows

Most people go through life without thinking about industrial chemicals, but chemicals like trichloroethylene end up touching lots of things—sometimes making daily tasks easier, sometimes stirring up concerns. Trichloroethylene, better known to folks in factories as TCE, carries a long track record in the manufacturing world. In my younger days working at an auto plant, I learned early on how important it was for mechanics to have spotless engine parts. Grease, dirt, and all else cleaned right up with a dunk in a tank filled with TCE. Job done faster, parts shining bright. Many shops still turn to TCE for degreasing metal before anything gets assembled. That quick cleaning saves time, but it’s tough to ignore the greasy chemical smell in the air.

Beyond the Shop Floor: Widespread Uses

Moving out of auto shops, TCE shows up in spots people don’t always expect. Dry cleaners for decades relied on it to power through stubborn stains on clothes. Even now, traces of that chemical hang on in parts of the textile world. Factories that make electronics and precision machinery want every component cleaned to almost surgical standards before soldering or wiring. TCE strips away oils left by handling or machining, leaving only clean metal behind. In these carefully controlled environments, even a fingerprint can mean the difference between a safe device and one that fails under pressure.

Health Issues Stay Close to Home

My own community faced a scare when a chemical plant nearby contaminated groundwater. The deeper the testing went, the clearer it became: TCE played a role. It leaches into soil and water. Even small exposures become a big deal if someone lives near old industrial sites. Cancer risks, nervous system troubles, headaches—these aren’t rumors. The U.S. Environmental Protection Agency and World Health Organization link long-term TCE exposure to real health threats. There’s something unsettling about a chemical with such useful properties also hanging over communities for years after a factory shuts down.

Cleaner Industry, Tough Choices

It’s easy to see why companies stuck by TCE for so long. Fast cleaning and cheap costs look good on paper. Yet, science keeps pushing industry to think twice. My old shop eventually went through a rough but necessary shift away from TCE, swapping methods and solvents. Lots of places now use water-based cleaners, citrus-based products, or superheated steam. A few still resist, worried change will cost more or slow production. Yet the price tag for cleanup, lawsuits, and workers’ health piles up higher than any up-front switch.

The Path Forward

Chemical safety needs stronger rules and honest talk. Watching TCE get banned or controlled in more states shows how society responds to proven risks. Stronger air monitoring, more regular soil and water testing, and real training for workers matter. Solving today’s mess involves remembering stories from both sides of the fence—engineers solving practical problems and families coping with chemical pollution. Rooting out these risks depends on responsibility at every level: government, business, and even folks who never set foot in a plant but drink the tap water every day.

Understanding What Trichloroethylene Is

Trichloroethylene, or TCE, often shows up in places most people never notice. Factories use it to strip grease from metal parts, and dry cleaners used it for decades before safer alternatives came along. I once talked with a mechanic whose shop had barrels of TCE decades ago. He remembers the sharp smell and how it cut through oil like nothing else. That convenience came with a hidden cost.

The Health Risks of TCE

TCE carries a reputation for being tough on grime, but it’s harder on the human body. Breathing its vapors or letting them soak into skin can send the chemical straight to your blood. Short-term exposure can leave someone dizzy or cause headaches, but the bigger problem lies in slow poisoning. The World Health Organization and the U.S. Environmental Protection Agency both call trichloroethylene a human carcinogen. These agencies don’t make such claims lightly; they’ve pulled together years of research, animal studies, and records from workers exposed over the span of their careers.

Cancer risk is not just theory here. Researchers have found more cases of kidney cancer, and a link to non-Hodgkin lymphoma and liver cancer, among workers handling TCE every week. Even at lower levels—like the contamination found in drinking water near old manufacturing plants—there’s worry. Over the years, I’ve met folks in small towns with polluted groundwater who still wonder whether their kids’ illnesses could tie back to TCE leaks from upstream factories.

Why TCE Still Matters

Some households might think this is only a factory problem, but TCE has a talent for sticking around long after factories close down. Because it doesn’t break down quickly underground, communities living near forgotten industrial sites end up at risk, too. In my own county, one patch of land stood empty for years because the soil couldn’t pass safety checks. The source? Decades-old TCE spills.

The chemical can travel through the soil and turn up as vapors inside buildings, a process called vapor intrusion. Families living in these homes can unknowingly breathe the chemical day after day. Stories have cropped up in the news about schools, offices, and homes needing expensive cleanups once TCE turns up in air tests.

Fixing the Problem

Turning a blind eye hasn’t worked. Keeping people safe starts with tracking down old spills and cleaning up the mess, even if it’s expensive. Some states require regular testing of groundwater and air inside homes built near former factories. Rules about handling TCE, stronger than those written in past decades, force businesses to find safer solvents or switch to water-based cleaners.

For people who spot odd-smelling water or learn about a history of chemical spills nearby, it makes sense to ask local health departments for information or water testing. Workers in industries that still use TCE—such as electronics or metalworking—should press for safety equipment and proper ventilation. Change happens when people speak up and push for answers. The science has made clear that safety can’t take a back seat to convenience or old habits.

Understanding Why It Matters

Plenty of products on factory floors would grind to a halt without trichloroethylene, better known as TCE. I’ve seen it used everywhere from metal shops cleaning engine parts to electronics factories stripping grease. The stuff works because it cuts through oil like nothing else. But with power like that comes risk. TCE carries weighty health hazards, no matter how often it shows up in industry. Breathing in its vapors, getting it on your skin, or spilling it by accident is a ticket to real trouble: headaches, dizziness, nausea, or worse with long exposure, including cancer and impacts on the nervous system. That risk isn’t just abstract, either. I’ve met workers who learned it the hard way.

Shaping Up on Storage

Storing TCE in the right way means fewer accidents and better health. Metal drums with tight-fitting lids do a good job keeping leaks in check. Stash those containers in a spot made for chemicals — far from drains, food, or worker traffic. I once watched a container stored next to a lunch table begin to leak and the fumes didn’t waste time spreading. You don’t want that. Ventilation pulls away the heavy vapors that sink to the floor. If you only have a fan and an open room, you’re asking for an unsafe buildup. On top of that, labeling the drums in plain language prevents mix-ups that could get someone sick or worse.

Take Spills Off the Table

Trichloroethylene does not forgive mistakes. Spill plans matter. Keeping a spill kit on hand with absorbent pads, gloves that don’t give up after two minutes, and proper goggles takes guesswork out of emergency cleanup. Used to think paper towels cut it — they don’t. If a spill ever happens, send fumes outside with a local exhaust or, even better, a fume hood. Once, I watched an untrained worker try to mop up a spill, and the mess sent fumes through the warehouse. Training saves money and lungs.

Keeping It Personal

Relying on thin gloves or afraid-to-speak-up attitudes leaves everyone exposed. Workers should always use real chemical-resistant gloves, sealed goggles, and an apron if there’s even a chance for spills or splashing. I once skipped gloves to “quickly” set aside a jug and noticed tingling fingers before I finished the job. Protecting your eyes, skin, and lungs beats taking shortcuts. TCE lingers and sticks to clothes, so a locker or changing area keeps exposure from reaching families at home.

Training is Non-Negotiable

Regulations from OSHA and EPA aim to keep TCE tragedies out of the news. The law doesn’t take ignorance as an excuse. Regular walk-throughs and training drills remind everyone about the real consequences of handling this chemical carelessly. A plastic sign won’t teach respect; real stories and hands-on drills do. Reporting leaks, labeling workspace zones, and demanding proper personal protective equipment make the difference between a safe shift and a lockout situation. The right attitude spreads fast and saves lives.

Smart Practices Make a Safer Workplace

Worrying less about storage leaks or sudden spills lets workers focus and breathe easy. Reducing exposure protects health for the long haul. No one should learn about the dangers of trichloroethylene by accident. Honest communication, reliable gear, clear spaces, and repeated practice put the control right where it belongs: in the hands of the people doing the job every day.

Understanding the Risks

Trichloroethylene, or TCE, doesn’t exactly belong in the same sentence as household cleaners. This chemical has been used for decades as an industrial degreaser, in dry cleaning, and sometimes as a solvent in laboratories. It’s effective at what it does, but it doesn’t pull any punches when it comes to potential health risks. Short-term exposure can make you feel dizzy, cause headaches or nausea, and give your lungs or skin a rough time. Breathing in too much TCE for too long brings bigger problems: liver or kidney damage, nerve issues, and it’s been linked to cancer according to the EPA and the World Health Organization. Those facts alone mean cutting corners with safety just isn’t an option.

Better Ventilation and Why It Matters

Few things make a job safer than letting some fresh air in. When TCE is used in a closed room, fumes can hang around invisible and unnoticed. Cracking open windows or giving the workspace ventilation systems, like proper exhaust fans, makes a big difference. Respirators step in when ventilation doesn’t cut it. Workers in factories or garages—anyone near vats of the stuff—should have access to air-purifying or supplied-air respirators rated for organic vapors. Relying on a simple dust mask won’t protect your lungs from TCE fumes.

Keeping Your Skin Covered

TCE doesn’t just target the airways. Skin contact might seem small at first, maybe some irritation, but over a work shift it can lead to more serious reactions or cause it to enter your system. Covering up with gloves made from materials like butyl rubber or Viton makes a big difference. Cheap latex or thin disposable gloves break down too quickly. Goggles and face shields keep TCE splashes out of your eyes, which can burn and sting right away. Changing out of any clothes that caught a spill stops TCE from sticking around on your skin or making its way home.

Storage and Spill Sense

Leaving a drum of TCE open isn’t just careless; it invites trouble. Chemical containers need tight-fitting lids. Store these in well-marked spots, away from heat and sunlight, because high temperatures turn small leaks into a big cloud of vapor. If there’s ever a spill, sand or absorbent pads catch and trap most of the liquid—the rest calls for cleaning products designed for chemical accidents. Never wash TCE spills down the drain. Local authorities can offer advice on hazardous waste pickup, and that’s information worth having before anything goes wrong.

Information and Training: Spreading the Word

People working around TCE deserve to know exactly what they’re dealing with. OSHA and NIOSH recommend regular training that explains not just the hazards, but how to use protective equipment, handle accidental exposure, and what steps to take during a spill. A good safety plan means everyone knows where to find eye wash stations, showers, or first aid kits. If someone feels sick during a shift, removing them from the area and seeking medical advice isn’t overreacting—it’s just the right thing to do.

What to Watch For

Chemicals like TCE don’t always give clear warning signs. Feeling lightheaded, coughs, or irritated skin shouldn’t be ignored. Sometimes those little symptoms speak louder about long-term health concerns. Keeping an eye out for each other, reporting issues early, and following up with health checks all help avoid problems that don’t show up until it’s too late to fix them.

Reducing Risk for Good

Finding alternatives is always worth a look. Some industries already moved away from TCE where they could, trading it for safer solvents and new technology. Until that shift gets widespread, following tough safety rules keeps people safe at work and protects families from dangerous chemicals hitching a ride home. That’s something every workplace can stand behind.

The Pressure to Move Away from TCE

Trichloroethylene, or TCE, earned its reputation as a powerful solvent. Machines, factories, and even some small garages leaned on it for degreasing engines, cleaning metal, and getting rid of stubborn grime. But I remember the first time I really read the safety sheet in a plant break room—it didn’t make my coffee go down any easier. The chemical connects to cancer and nerve problems, and that’s not just from one study. The International Agency for Research on Cancer classified TCE as a Group 1 carcinogen. No one should have to work in a cloud of worry, so it’s a good moment to consider better alternatives.

Switching to Aqueous Cleaners

Water-based (aqueous) cleaners make the top of the list for a reason. I’ve cleaned greasy valves and pipes with these solutions in food factories and bike repair shops. Properly formulated products, mixed with detergents, eat up oil and dirt without sticking around in the air like TCE does. With hot water, agitation, and surfactants, they get the job done for most parts and surfaces. Professional auto shops switched to these blends years ago. The carbon footprint drops, hazards shrink, and the stuff rinses away. Proper wastewater treatment matters—what’s washed down the drain shouldn’t just end up in the river—but compared to the headaches of VOCs and toxic vapors, that extra step is manageable.

Exploring Bio-Based Solvents

Natural cleaning solutions often get the side-eye for being “greenwashed,” but close inspection reveals real progress. D-limonene, a citrus-based solvent pulled from orange peels, wipes away adhesives and degreases gears surprisingly well. Soy-based products carry their own power; they soften oil, asphalt, and even paint residues. I’ve seen crews in maintenance yards favor these because the fumes don’t stink up the entire shop, and the health complaints fell off a cliff once the switch happened. These choices break down faster in the environment, and you can actually breathe a little easier around them.

Hydrocarbon Choices and Alcohol-Based Cleaners

Hydrocarbon solvents like mineral spirits and naphtha clean tough parts, but anyone who’s spent a day in a warehouse knows the fire risks and fumes can become a headache. Newer grades with lower aromatic content cut down on some danger but nothing wipes away flammability concerns. For lighter jobs—circuit boards, glass surfaces, and electronics—alcohol-based cleaners like isopropyl alcohol take center stage. Hospitals use these for everyday cleaning. These evaporate clean, don’t leave much residue, and short exposures rarely cause harm.

Finding the Right Fit and Keeping Safety in Focus

No single chemical lines up as the perfect drop-in answer for TCE. Each industry faces its own dirt, grease, old paint, and sticky tape. Trying out a few options, thinking about PPE, and reading those safety sheets closely always pays off. The push for safer chemicals came from people who spent years breathing fumes and watching coworkers call out sick. Long-term safety and health impact should drive the switch, not just short-term cost. OSHA and EPA increase the pressure; lawsuits and cleanup bills drive it home.

Working Toward Cleaner Workplaces

Choosing smarter, safer alternatives goes farther than switching one solvent for another. Training counts, so does protective gear. Companies that invest in equipment to use less solvent—like ultrasonic cleaners or vapor degreasers with built-in recycling—see the benefits add up. The move away from trichloroethylene feels overdue. People deserve both clean parts and clean air at work.