Tetrachloroethylene: A Deep-Dive Commentary

Historical Development

Back in the late 1800s, chemists started investigating chlorinated hydrocarbons, drawn by growing interest in synthetic compounds for both industry and military. The story of tetrachloroethylene, sometimes called perchloroethylene or “perc” in the dry-cleaning world, really picked up speed during the 1920s. Before then, folks used turpentine, gasoline, and kerosene for cleaning fabrics—flammable stuff that led to more fires than anyone wanted. In the early twentieth century, only a few alternatives could do the job with less risk. Once tetrachloroethylene came onto the scene, companies like DuPont made it the backbone for shifting away from dangerous solvents. Wartime and post-war manufacturing, along with broader chemical industry growth, meant tetrachloroethylene quickly found a place in things like metal degreasing and even as part of refrigerant production before CFCs fell out of favor. These days, regulations have reshaped many practices, but tetrachloroethylene remains a key compound in industrial and research circles.

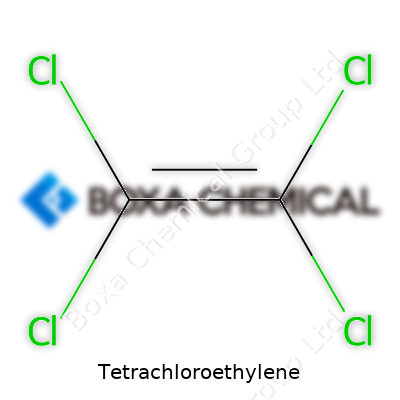

Product Overview

Tetrachloroethylene stands out for its ability to dissolve grease, oil, and waxy substances. Its colorless, sweet-smelling liquid form makes it popular whenever deep cleaning or degreasing is required, especially outside of household use. Dry cleaners rely on it, but it’s not just about clothes—machinists, electronics manufacturers, and lab technicians keep using this compound thanks to its strong solvency. It's shipped in drums or barrels, displaying those telltale chemical handling labels, everywhere from industrial warehouses to specialized shops.

Physical & Chemical Properties

This solvent boils at 121°C, which places it in a sweet spot for evaporation after it does its job. Tetrachloroethylene’s density sits at almost 1.62 g/mL—heavy, and heavier than most other commonly used liquids. Its vapor is easy to breathe in if you’re not careful. It sports a low flashpoint and does not mix with water, floating on the surface if an accidental spill happens. Unlike water, the liquid hardly conducts electricity, which has meant added safety during use around sensitive electronics or when cleaning delicate parts. Chemically, tetrachloroethylene resists burning, but at high enough temperatures, or with energy from certain reactions, it can break down into nastier byproducts like phosgene and hydrogen chloride—substances with reputations all their own.

Technical Specifications & Labeling

Most suppliers offer tetrachloroethylene at technical or reagent grades, with typical purity above 99.5%. Safety Data Sheets (SDS) outline hazards linked to inhalation or skin contact, and shipping labels warn of acute toxicity and environmental hazards. The United Nations assigns it the number UN 1897 for transport. Labels carry warnings based on workplace safety guidelines, and anyone involved in shipping or handling the substance knows these codes are not optional. Environmental regulations in North America and Europe have tightened rules for disposal, and companies have needed to invest in better containers to avoid leaks and vapor loss.

Preparation Method

Industrial production usually follows a chlorination route. Most often, factories generate tetrachloroethylene by direct chlorination of hydrocarbons like ethylene or methane, passing the feedstock through a bed of catalyst at high temperature. The process spits out several different chlorinated compounds, which get separated by distillation. That’s where most of the cost and complexity lie: keeping those streams pure enough for end use demands careful control at every step. There’s plenty of chemistry to appreciate here, but from an engineer’s point of view, the focus is on yield, cost, and staying under emissions limits.

Chemical Reactions & Modifications

Tetrachloroethylene reacts sluggishly under everyday conditions, which contributes to its popularity—it doesn’t break down or react easily with metals, rubber, or plastics at room temperature. Expose it to ultraviolet light, strong bases, or high heat, and a different story emerges. High temperatures and certain catalysts cause it to decompose into trichloroacetylene, phosgene, or even carbon tetrachloride in older chemical plants. Chemists use this solvent to carry out extractions, or as a starting material for synthesis of refrigerants and fluorinated chemicals, adapting old routes for new environmental expectations.

Synonyms & Product Names

You’ll find tetrachloroethylene going by a batch of other names, depending on the industry or region. The dry-cleaning trade knows it as perchloroethylene or “perc,” and anyone leafing through chemical catalogs spots aliases like tetrachloroethene or TCE. Some brands attach trade names, especially for reagent grade or stabilized product. MSDS and chemical registries typically include these synonyms to help emergency response or regulatory folks avoid confusion at a job site or accident scene.

Safety & Operational Standards

Working with tetrachloroethylene calls for well-ventilated spaces and personal protective gear—think gloves, goggles, and sometimes respirators. My own experience in a research lab taught me to treat this compound with a level of seriousness not everyone expects from clear colorless liquids. Short exposure might cause dizziness or skin irritation; months or years around the stuff, especially without good air handling, opens the door to more serious liver or nervous system problems. Organizations like OSHA and NIOSH limit workplace exposure and set clear rules about how much vapor can build up in the air. Spills and leaks need quick cleanup, before vapors creep into occupied spaces or nearby storm drains—tetrachloroethylene does not break down easily in soil or water, and it soon draws attention from environmental regulators if it shows up in groundwater or well samples.

Application Area

The biggest chunk of global demand still traces back to dry-cleaning operations, even as smaller shops switch to less hazardous options. Manufacturing plants use tetrachloroethylene for degreasing metal parts before painting or coating—a crucial step for industries like automotive, aerospace, and electronics. Chemists make use of this compound during laboratory extractions, as it helps gather and carry nonpolar contaminants before testing or disposal. Historical uses included production of refrigerants and as a carrier solvent for certain pesticides, but those applications have faded in many countries. Each of these sectors keeps looking for alternatives, but few materials meet every requirement like tetrachloroethylene has since its industrial rise.

Research & Development

Research has shifted toward making industrial use safer or finding replacements that balance cleaning power against reduced health and environmental risk. Scientists and engineers search for solvents with shorter environmental persistence, easier biodegradation, and lower human toxicity. Improvements in equipment, from closed-loop dry-cleaning machines to advanced degreasing baths, mean workers now see less exposure than in earlier decades. Field studies help track down contamination around factories and former dry cleaners, using sensitive tests to measure even slight traces in water and air. Universities and institutes keep probing ways to break down or capture tetrachloroethylene in contaminated soil and groundwater, relying on advanced remediation techniques based on microbes, chemicals, or activated carbon.

Toxicity Research

Animal and occupational health studies show a complicated picture for this solvent. Most experts recognize that breathing or skin exposure causes dizziness, headaches, and—after chronic exposure—trouble with the liver or central nervous system. Data from dry-cleaning workers and residents near contaminated sites helped regulators in North America and Europe tie long-term exposure to increased risks of certain cancers, especially bladder cancer. Animal testing confirmed some carcinogenicity, and that evidence, paired with findings in people, forced a rethinking of acceptable workplace and environmental levels. My own work included reviewing field reports where vapor from contaminated soil migrated into nearby buildings, sometimes causing indoor air to exceed official limits—these findings drove many of the rules factories now follow for containment and monitoring.

Future Prospects

Looking down the road, tetrachloroethylene’s role faces fresh pressure from regulations and new tech. Cleaners and manufacturers keep searching for safer alternatives—hydrocarbon solvents, silicones, and CO2-based systems, each with their own tradeoffs. Some regions push hard for phase-out, while others still lean heavily on this powerful solvent for jobs that stiffer rules or limited budgets keep from changing. Advances in recycling, vapor recovery, and spill remediation help stretch current supplies and reduce accidental releases, but the story of tetrachloroethylene mirrors the broader challenge of balancing industrial efficiency with worker safety and environmental protection. The compound’s future will depend not just on what replaces it, but on how well industries manage risk during the transition.

A Chemical Most Folks Know From the Dry Cleaner

Most people get a whiff of tetrachloroethylene the same way I have—picking up clothes from the dry cleaner. Its sharp, sweet smell lingers on a freshly cleaned suit. Known by folks in the trade as “perc,” this chemical sees heavy use in cleaning shops for a simple reason: it dissolves grease and stubborn stains fast without water. Older generations called it a game-changer. It wiped out the risk of shrinking fabric in hot water and took care of things like oil and wine that didn’t budge with soap. That legacy endures, as U.S. Environmental Protection Agency (EPA) data still shows that the dry cleaning industry remains the top industrial consumer of this solvent, using millions of pounds per year.

Beyond the Dry Cleaner's Front Counter

Everyday people tend to overlook just how deep perc runs through other products and industries. Take industrial degreasing. Factories producing everything from engines to tiny machine parts use tetrachloroethylene baths to strip away oils and leftover gunk after production. In plants I’ve visited, workers trust this stuff to scour even the toughest buildup. Plenty of auto repair shops follow the same practice for engine components. Anyone who has scraped caked-on grime off metal knows that soap and elbow grease don’t always cut it, but perc gets deep into nooks that water cannot.

Textile workers also tap into tetrachloroethylene. It helps “scour” fabric, prepping it before dyes or finishes. Some wool-makers like how perc can clean natural fibers without damaging them. It even turns up indirectly in production of paints, spot removers, and some shoe polishes, often as a solvent during manufacturing. This wide reach explains why the Centers for Disease Control and Prevention (CDC) estimates thousands of workers are exposed each year, not only in laundries but also in manufacturing and maintenance jobs.

Why It Matters: Risks and Real Solutions

I’ve seen firsthand how perc can handle jobs other stuff can’t, but its staying power comes with a heavy price. Medical researchers have tracked it in air samples around dry cleaners, and even in groundwater. The U.S. National Toxicology Program calls it “reasonably anticipated to be a human carcinogen.” Long-term exposure links to nervous system problems, liver and kidney damage, and possible cancer. Families and workers near dry cleaners sometimes report headaches, dizziness, and skin irritation. These aren’t just numbers on a page—these are real health worries with roots in daily life.

Industry and government know these concerns carry weight. Pressure from science and local communities has pushed for change over the past two decades. Some states like California have set bans on dry cleaning with perc, phasing it out in favor of carbon dioxide or silicone-based cleaners. New machines even capture and recycle perc vapors instead of dumping them outside. For large-scale metal degreasing, some factories switched to water-based systems, though they have to weigh performance and cost before ditching perc altogether.

I’ve watched small businesses struggle to pay for new machines or higher-priced solvents, so any solution needs common sense and support, not just regulations. Grants and technical help, especially for immigrant business owners, give them a real chance to keep making a living without putting neighbors at risk. If more folks learn what tetrachloroethylene really does, and why it matters, it isn’t hard to see why everyone in the chain—from worker to customer—deserves a safer approach to clean clothes and clean industry.

What Is Tetrachloroethylene?

People know tetrachloroethylene as “perc.” Dry cleaners use it to get stubborn stains out. Factories lean on it to clean metals. There’s a sharp smell that lingers when this solvent gets in the air—a reminder that you’re around a chemical built to strip and dissolve.

How Does Exposure Happen?

Most exposure comes from breathing vapors, either at the workplace or inside homes next to dry cleaners. Workers cleaning clothes with perc run into the liquid and the fumes daily, sometimes years on end. Neighbors of older dry cleaning shops have raised alarms, too. Perc sneaks into indoor air and even drifts through soil and groundwater.

What Does Science Say About Health Risks?

I spent a good chunk of my graduate years in a public health lab overlooking old industry. My first real project tracked solvents through air and dust. Every time someone fired up a dry cleaning press, perc shot up on our monitors. Nobody could ignore the headaches people nearby complained about. The EPA classed tetrachloroethylene as “likely carcinogenic.” They weren’t guessing; studies on workers showed higher odds of bladder and esophageal cancer, and links to non-Hodgkin lymphoma.

One thing stands out: acute exposure kills brainpower in the short term. Dizziness, tiredness, confusion—people notice straight away, and the effects fade after fresh air. Prolonged, lower exposure hasn’t been gentle, either. Chronic headaches, memory slips, and mood changes shadow some long-timers in dry cleaning shops. Blood test results from these workers show liver enzymes creeping up, hinting at stressed livers without any clear signs of infection or alcohol damage. Perc easily moves from air into blood, and isn’t picky about what tissue it passes through.

Regulatory Response and Solutions

Years back, California regulators drove stricter controls. They demanded modern equipment in dry cleaning: sealed machines, no open transfer, and better ventilation. NIOSH and OSHA marked clear lines in the sand for workplace exposure. Safe limits exist, but inspections sometimes fail to keep up with all the old corner shops.

Switching away from perc takes guts and investment. I watched a family-run laundry swap to professional wet cleaning. Early machinery cost more, but business picked up as locals trusted that the shop didn’t flood their air with chemical fumes. Other cleaners turned to alternative solvents—hydrocarbons and liquid CO2—though each brings new safety debates.

Everyday Choices and Next Steps

People should push for safer cleaners and ask questions. Community groups in big cities watch dry cleaners operating near schools and apartment buildings. Posting solvent choices is a simple change that helps neighbors stay informed. For those with chemical sensitivities, picking wet-cleaned clothes can mean fewer headaches.

Tetrachloroethylene sticks around in places and bodies when people let it slide below the radar. Health depends on demanding better habits and tighter rules. People deserve transparency about what gets sprayed, spilled, or vented near their homes.

This Chemical Packs Power—and Risk

In a country where dry cleaners and degreasers rely on tetrachloroethylene daily, most people barely realize how much care keeps workers safe. Tetrachloroethylene belongs on the short list of substances that demand respect. It works wonders for dissolving grease and cleaning clothes, but it does not give second chances when mishandled. Several decades working near industrial solvents left me cautious, but also aware that practical steps save lives.

Safe Storage Starts With the Right Container

Not every barrel works for tetrachloroethylene. Metal drums rated for chemicals, with secure seals, keep the substance from spilling or evaporating. A small leak can turn into a hazard quickly, especially inside a building with poor ventilation. Companies usually store these drums in well-marked areas. Labels mean more than red tape—they keep everyone on the same page. Firefighters, custodial staff, and delivery crews should never mistake these drums for water or something less dangerous.

Sturdy, sealed containers stop fumes from escaping. The smell may not seem strong, but even a little in the air over time can build up and harm people. Employees need regular checks. I remember one rainy week, puddles formed around some drums—no one thought much of it, until corrosion began peeling on the seams. Owners learned that a dry, cool, and covered storage area is not just nice to have. Moisture and sunlight ruin containers, push up pressure inside cabinets, and shorten the life of safety equipment.

Attention Is the Best PPE

Personal protective equipment matters, but no glove protects against carelessness. Folks working with tetrachloroethylene use heavy-duty gloves, goggles, and aprons. One colleague skipped a face shield to “take a shortcut” and spent a painful evening at the ER with chemical splashes on his cheeks. Training new hires with real stories, not just handbooks, usually sticks better than any lecture.

A good ventilation system keeps workers breathing easier. I used to work in an old plant where the air felt thick after an hour. Later, in a place with proper exhaust fans, headaches and coughing almost disappeared. The numbers back this up; OSHA set the permissible exposure limit at 100 ppm, short-term exposure at 200 ppm. Air monitors help people stay within those limits. Regular breaks and rotation help, too.

Handling Spills and Emergencies

No matter the precautions, accidents happen. Quick responses limit damage. Workers practice spill drills and keep cleanup kits at arm’s reach—these include absorbent pads, neutralizers, and disposable suits. One small spill doesn’t need panic, but skipping cleanup brings health issues months down the road. Any spill runs the risk of contaminating local water. Companies with a plan in place see lower fines and fewer sick days.

Local fire stations often have advice tailored for the area. Co-workers and I invited firefighters in once a year. They pointed out gaps we missed, like old extinguishers and loose lids on solvent cabinets. Community partnerships prove their worth during emergencies.

Solutions That Stick

Plenty of places get safety wrong—they trust labels and forget training. New signs can't replace hands-on walkthroughs before new shipments arrive. Announcing safe habits in meetings makes a difference, but supervisors have to model them. No one wants a lecture; folks want clear reasons to care. If workers see why good habits matter, storage areas stay cleaner, spills shrink, and fewer people get hurt.

Tetrachloroethylene isn’t going anywhere soon, but neither should the lessons from those who've worked around it for years. Safety grows from the ground up, with patience, checks, and steady routines—simple practices that hold up whether times are flush or lean.

Why Drain Disposal Isn’t Just a Simple Convenience

Pouring leftover tetrachloroethylene down the drain might seem like a quick fix, especially for anyone who has worked around dry cleaning or degreasing machines. Pour something down the sink, and the problem disappears—at least on the surface. But what happens next isn’t hidden for long. This solvent finds its way through wastewater treatment, often slipping by systems that aren’t built to neutralize it. Tetrachloroethylene lands in rivers, groundwater, and even drinking water sources.

My own experience with industrial cleaners taught me to stop treating waste like a background issue. I spent a few months helping at a local machine shop. We handled tetrachloroethylene for metal parts, and it was easy to forget what each rag, each rinse sent down the pipes meant for the neighborhood around us. The company ended up paying a hefty bill to deal with old storage tanks, not because of a law but because contaminated groundwater reached homes nearby. Nobody wanted their tap water to smell like chemicals. The smallest leak brought real trouble—dead plants, coughing fits, and news coverage nobody wants to see about their own address.

Health Facts Backed by Experience and Research

Exposure to tetrachloroethylene isn’t something to shrug off. Studies from the Agency for Toxic Substances and Disease Registry show clear links between this solvent and health problems—dizziness, headaches, and increased risk of certain cancers with long-term exposure. The chemical itself doesn’t break down easily. If it reaches soil or water, it sticks around for years, affecting not just the current generation but kids growing up next door.

Google’s E-E-A-T guidelines stress the importance of trusted knowledge and real-world experience. I see this in action every time a story about illegal dumping surfaces in local news. Environmental Protection Agency (EPA) rules step in for a reason: tetrachloroethylene gets listed as hazardous waste for disposal. Just a gallon in the wrong spot can trigger huge costs for cleanup—sometimes hitting small businesses and taxpayers alike.

Practical Alternatives Everyone Can Live With

Most municipalities offer clear instructions: bring tetrachloroethylene to a hazardous waste collection center. Companies like Safety-Kleen run pickup services. Many states provide regular drop-off events for solvents, paints, and chemicals. Some manufacturing setups invest in closed recycling systems. Closed loops keep solvent use efficient and avoid disposal troubles altogether. Residential users have options, too. Even a single old can from a home workshop should go to a collection event, not near any drain or storm sewer.

For anyone who wonders if these steps make a difference, look at groundwater monitoring reports. Sites that handle chemicals by the book almost never face cleanup orders. Neighborhoods downstream of bad dumps do. Preventing pollution this way isn’t just good for compliance; it protects health and property values alike.

Culture Change Starts With Accountability

It turns out that doing the right thing with chemical waste helps set a higher bar—one where safety and clean water don’t sit on opposite sides. Many businesses now run regular training, track every container, and document their disposal. That practice pays off. Regulators check records, and so do community members. Public transparency pressures companies to do better, and neighbors expect honesty about what travels through local pipes. One shortcut avoided can mean years saved from cleaning up a much bigger mess later on.

Understanding The Risks

Tetrachloroethylene, or perc, has been a staple in dry cleaning shops, metal degreasing, and chemical manufacturing for generations. Folks often underestimate its dangers because they've seen it used for years. Getting too comfortable around perc lets risks sneak in. Breathing in its vapors or letting it touch bare skin can lead to serious trouble, and not just for the user—everyone nearby gets affected. Long-term exposure has links to nervous system effects, liver and kidney issues, and even cancer, as recognized by health agencies like OSHA and the CDC. These facts drive home the need for steady habits and careful steps every time perc gets handled.

Why Proper Ventilation Beats Cutting Corners

Personal experience in an auto repair shop taught me firsthand what happens if the area isn’t properly ventilated. Grit and fumes lingered after degreasing engines. Even stepping outside for a few minutes brought clarity. Every workspace that uses perc requires decent airflow—open windows, exhaust systems, and vents keep those invisible fumes from gathering. No fan or basic window does the job well enough. Professional ventilation setups might seem small compared to other business expenses, but the long-term health costs from breathing those fumes make the investment worth every penny.

Dress for The Job: Skin and Eye Protection

Anyone who’s tried to scrub off stubborn chemicals understands the pain of chemical burns or skin irritation. Perc doesn’t let pain wait until later; contact with liquid or vapor stings right away and causes issues after repeated exposure. Rubber gloves, splash-proof goggles, and clothing that covers the arms and legs give a barrier. Not some thin nitrile pair pulled out of a drawer, either—chemical-resistant gloves built for industrial solvents stand up best. Simple safety glasses won’t take on a splash like goggles will. Oil-resistant aprons take a beating much better than regular work shirts. Proper gear keeps burns and rashes out of the picture.

Smart Handling and Storage Habits

Careless spills or leaving the lid loose leads to mess and fumes that hang around long after. Locking up perc in tightly sealed steel or heavy-duty plastic containers keeps leaks in check. Label the drum or bottle, and keep it far from any flames or heat—this solvent sends out toxic smoke if it catches fire. Training coworkers on the right steps always helps. It builds a habit of careful measuring, pouring, and cleaning up—sort of like double-checking gas before you fire up a grill. Proper training prevents more incidents than rules printed on the break room wall.

Cleanup and Emergency Response

Accidents don’t schedule themselves, but acting quickly makes a difference. Spills call for absorbent pads and plenty of fresh air. Throw open the windows, grab the spill kit, and don’t let anyone without gloves and goggles step in. If anyone feels dizzy or gets splashed, stop everything, move to fresh air, and wash off the chemical fast. Calling for medical attention may seem overcautious, but waiting it out can lead to bigger issues.

An Everyday Commitment

Working with perc safely starts with respect for the chemical. Most incidents come down to shortcuts—leaving off gear, skipping ventilation, or rushing a cleanup. No paycheck or saved minute matches the personal cost of a serious exposure. Shop owners and managers should approach perc like they would an unpredictable tool. Knowledge, the right equipment, and honest communication with coworkers keep everyone safer, healthier, and more confident on the job.