Polypropylene Carbonate: A Close Look into an Evolving Polymer

Historical Development

Polypropylene carbonate came onto the scene right as chemists and engineers saw the need for more sustainable, environmentally friendly polymers. The path from early research to current commercial products tells a story packed with science, persistence, and the pressure to address carbon emissions outright. In the 1950s and 60s, scientists began to experiment with copolymerization of carbon dioxide and epoxides. Most early work relied on simple catalysts, which couldn’t quite handle the job efficiently. Breakthroughs followed in the late 1980s with the development of more sophisticated catalysts—specially tailored metal complexes. These advances provided dependable routes for turning CO₂ and propylene oxide into long chains of polypropylene carbonate, nudging chemical manufacturers toward large-scale production. Over decades, multiple research groups and major chemical companies fine-tuned production, wrestled with scaling up reactors, and established technical standards. As fossil-fuel sustainability transformed into a big industry target, polypropylene carbonate products earned more attention, both as a standalone material and in blends.

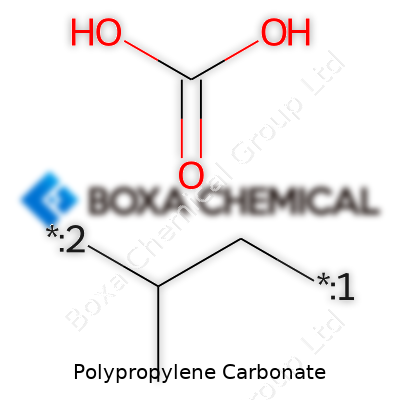

Product Overview

Polypropylene carbonate is a thermoplastic copolymer. It emerges from combining carbon dioxide and propylene oxide using controlled catalytic polymerization. It looks like tiny white granules or smooth pellets, and its touch feels almost waxy, softer than most common plastics. The material is compostable under the right conditions, offering a way to put waste CO₂ to use while easing pressure on landfills. Unlike other commodity plastics like polyethylene or polystyrene, polypropylene carbonate delivers moderate strength, good flexibility, and remarkable optical clarity. These traits open doors in packaging, adhesives, films, and as biodegradable fillers in everyday items.

Physical & Chemical Properties

Polypropylene carbonate’s density sits near 1.15 g/cm³, which makes it heavier than conventional polyolefins. Its softening point runs from 90°C to 110°C, lower than most engineering plastics. Elongation at break goes above 200%, providing notable flexibility and stretch before snapping. In my lab years, pulling thin films through tensile testers, I noticed they don’t shatter easily. Moisture uptake remains low, so dimensional issues under humid conditions stay minimal. The polymer resists many oils and greases, thanks to its carbonate linkages. It dissolves in select organic solvents such as acetone and some chlorinated fluids, giving processing engineers good choices during manufacturing. Polypropylene carbonate breaks down at higher temperatures, starting to decompose above 180°C—a good fit for applications not exposed to extreme heat.

Technical Specifications & Labeling

Resin grades of polypropylene carbonate often come with melt flow indices ranging from 3 to 7 g/10 min. Sheet and film producers need clear labeling on packaging to handle compostability, thickness, and recyclability. Most commercial forms indicate additive content, such as impact modifiers or plasticizers, right on spec sheets. Lots produced for medical or food packaging applications call out detailed impurity profiles, reflecting strict safety standards. Material safety data sheets (MSDS) alert handlers to the polymer’s behavior during heating, including safe processing temperatures and required ventilation during melt operations.

Preparation Method

Producing polypropylene carbonate starts by feeding a reactor with purified carbon dioxide and propylene oxide along with a sophisticated catalyst, usually based on zinc or cobalt complexes. The process presses CO₂ into liquid or supercritical states so it upholds strong contact with the liquid monomer. Within a controlled temperature window, the catalyst links monomer units, extending the polymer chain and trapping carbon dioxide within it. The result pours into a quenching mixer, sometimes in the form of a thick slurry, where the catalyst deactivates and the polymer precipitates out. Next, you wash and dry the powder, and then granulate it into manageable pellets. In my own hands-on experience, overseeing polymerization runs, pressure, purity, and catalyst residue management always take front seat to keep the end material free of color, off smells, or mechanical weakness. After granulation, manufacturers tailor additives and manage coloring agents for specialty applications.

Chemical Reactions & Modifications

This polymer’s backbone includes repeat carbonate groups, making it ripe for chemical tweaks. Common modifications involve blending with other biodegradable resins—like PLA or starch—which alter processing ease, physical toughness, and composting rates. Some research teams graft side chains onto the backbone, tuning performance for weather resistance or adhesion. In adhesive and coating labs, adding small molecules or reactive agents creates cross-linked networks, boosting barrier strength or water resistance. Polypropylene carbonate can react with acid chlorides to introduce carboxyl end groups, creating new options for compatibilization with other plastics. Throughout manufacturing, maintaining a careful eye on heat and moisture exposure keeps chemical structure intact—one step too much and the material can yellow or lose integrity.

Synonyms & Product Names

Across industry literature and commercial catalogs, polypropylene carbonate appears under several names. Some refer to it as PPC, others stick to chemical shorthand like poly(propylene carbonate). Branded products include Novomer, GreenPol, and EnaPol. I’ve seen some marketing teams roll out trade names emphasizing ‘carbon capture’ or ‘green polycarbonates’ to draw attention to the CO₂ utilization aspect. Despite the assortment of labels, the core chemistry remains consistent—the result of simple epoxide/CO₂ copolymerization.

Safety & Operational Standards

Production plants and technical staff working with polypropylene carbonate rely on up-to-date safety protocols. During synthesis, pressure vessels, proper ventilation, and carbon dioxide monitoring are critical. Dust from pellets or powder processing can pose inhalation risks, so effective dust extraction is mandatory. In processing, heating zones in extruders and injection molders must avoid thermal runaways above decomposition points, since some toxic fumes—mainly carbon monoxide and small aldehydes—can crop up at the upper limits. I’ve worked in pilot plants where strict housekeeping and regular checks went a long way to preventing product contamination and safeguarding health. For finished products, food and medical uses demand compliance with FDA or EFSA regulations, including migration tests and certifications for compostability.

Application Area

You’ll find polypropylene carbonate across a surprising range of sectors. In packaging, clear compostable films and foam tableware appeal directly to environmentally-minded consumers. Electronics applications benefit from its dielectric properties, offering antistatic layers or encapsulation for circuit boards. As a binder, it strengthens lithium-ion battery electrodes without leaving persistent residues. In construction, mixing polypropylene carbonate with cement improves workability and enables partial CO₂ sequestration. Other uses include drug delivery films, biodegradable microbeads, medical wound dressings, and as a solvent-friendly additive in coatings or paints. In my conversations with materials engineers, incorporating this material into existing production lines offers a middle path between legacy plastics and complete compostable solutions.

Research & Development

A great deal of current research focuses on catalyst design—crucial for commercial success. Researchers seek ways to turn more CO₂ into polymer at lower costs. Scientists at university and corporate labs push for breakthroughs in single-site catalysts, aiming to push up molecular weights and tailor mechanical resilience. Many projects explore blending with plant-derived polymers, hoping the synergy creates fully compostable composites without losing toughness. Other studies dig into surface modifications, improving paint adhesion, printability, or even the ability to hold nanomaterials in medical sensors. A recurring theme in conferences and journals centers around commercializing CO₂-sourced monomers and reducing reliance on petroleum production streams. The innovation cycle remains driven by real-world needs: sustainable supply chains, energy efficiency, and functional traits that meet growing environmental regulations.

Toxicity Research

Assessing toxicity matters for every new polymer. Toxicology data on polypropylene carbonate, both as pure resin and in blends, shows a reassuring safety profile. Animal and cell culture studies—often summarized by agencies like ECHA or US EPA—indicate low acute toxicity. The polymer does not bioaccumulate and breaks down into benign fragments through hydrolysis under composting conditions. Residual monomer content and catalyst traces always need control, so high purity standards rule specialty and food-contact grades. In my fieldwork, handling off-gassing during pelletization prompted careful air monitoring and scrupulous control of downstream emissions. As with many plastics, burnt or overheated residues can release lung irritants, so safe use practices always remain relevant.

Future Prospects

Looking forward, polypropylene carbonate promises to carve out a bigger role in new-generation sustainable plastics. Stricter climate policies and public demand for green products will draw attention to CO₂-based polymers. Manufacturing costs, recycling stream compatibility, and mechanical property enhancement will guide industry adoption. Emerging catalyst science and advances in reactive blending may unlock entirely new performance windows and push polypropylene carbonate into engineering and specialty markets. If municipal composting facilities expand their capabilities, end-of-life disposal hurdles will ease. By staying close to market feedback, industry can guide tweaks to processing and product design. All signs suggest that polypropylene carbonate’s story is still unfolding, shaped by global efforts to decarbonize and refresh materials science with practical, low-impact choices.

Why Polypropylene Carbonate Matters in Our Daily Lives

Polypropylene carbonate, or PPC for those in the know, isn’t just another plastic. It starts life from carbon dioxide and propylene oxide—right there, it stands out in a world used to relying on old-school oil. For folks paying attention to the climate, the idea of reusing CO2 gets a thumbs up. It’s exciting to watch science take something seen as a problem and put it to work.

Tough Jobs, Soft Touch: Packaging That Respects the Planet

Step into any shipping department or grocery aisle, and plastic packaging stares right back. Plenty of these wraps and films go straight to landfill. Over the past decade, PPC-based films and bags have eased that guilt for some. They break down faster than most regular plastics, growing in popularity among companies that want to showcase a green image. I’ve seen more brands switch to biodegradable packing peanuts and clamshells—often, PPC sits in the mix with starch or PLA to hit performance and composting goals. These options cut microplastic pollution, shrinking the waste pile in landfills.

Foams That Don’t Stick Around Forever

Insulation and disposable cups demand light, sturdy foams. Standard foams, once trashed, stick with us for decades. PPC foam, though, offers a way out. It handles coffee heat and insulation jobs, then fades in industrial compost. Cities aiming for greener events or builders tackling eco-certifications have started looking for these alternatives. Some manufacturers use PPC foam in electronics packaging, not just for its green story but also because it handles static and cushions gear on the move.

Adhesives, Inks, and Coatings That Pull Their Weight

Walk into a print shop, and solvents hang in the air. Old-style inks and coatings don’t come off as friendly—PPC, on the other hand, works as a binder and dispersant in water-based inks and paints. It keeps pigments in line, gives a smooth finish, and still washes away with a bit of effort. I’ve met artists and printers who say PPC lets their products meet tough indoor air quality targets, and parents appreciate washable children’s paints that work without harsh chemicals.

Medicine and Microelectronics: Small Pieces, Big Impact

In labs and cleanrooms, trace contamination spells disaster. PPC, with its low residue and easy processing, makes custom microspheres for drug delivery work and coatings on circuit boards seamless. Working in a research setting, reliable, safe materials are vital—PPC helps us carry drugs where they’re needed and protects the tiny circuits powering everything from hospital equipment to smartphones.

What Still Needs Work

Though PPC brings a lot to the table, scaling up production and keeping costs low challenge every new material. Right now, plant operators keep tuning the recipe to boost strength and push prices down. Recycling streams are slowly catching up. Some call for governments and industry leaders to invest more in PPC processing tech, while teachers and advocates remind us that supporting products made from PPC sends the right message: cleaner chemistry grows from both sides—the lab and the checkout counter. Watch this space, because more innovation is sure to follow as greener plastics edge out the old guard.

Everyday Plastics and Our Environment

Plastics show up everywhere — in packaging, electronics, furniture, toys, and mountains of single-use items. As someone who has spent years sorting household waste, I’ve watched with concern as bins fill with plastic wraps and bottles. The underlying problem isn’t just litter; it’s what happens to these materials long after they leave our hands. Some stick around in landfills or oceans for centuries. The search for biodegradable plastics gives people hope, but the truth often gets tangled up in technical terms and marketing claims. Polypropylene carbonate (PPC) steps into the spotlight here, promising a new story for plastics and waste.

What Sets Polypropylene Carbonate Apart

PPC’s chemistry isn’t what most shoppers know, yet it makes a world of difference in waste disposal. PPC forms through linking carbon dioxide with propylene oxide — so it traps otherwise harmful greenhouse gas inside its backbone. That connection doesn’t just lower its raw materials’ carbon footprint; it also lets the structure break down through the right microbial action. Some companies push PPC as an answer to issues with old-school plastics, especially in food wrap and certain foams.

The Biodegradability Question

Biodegradability confuses people, and for good reason. Tossing a plastic fork into your backyard compost doesn’t guarantee anything. For PPC, things look better than with things like polyethylene or polystyrene. Multiple studies back up PPC’s ability to break down in environments like compost piles or soil, given the presence of bacteria and the right warmth and moisture. Pieces of PPC decompose into water, carbon dioxide, and biomass, leaving no toxic stuff behind — at least under managed conditions.

I’ve tried normal backyard composting, and stubborn remnants from supposedly compostable plastics often remain after months. Lab results on PPC, though, often feature industrial composters with controlled heat and plenty of active microbes. In these places, PPC can disappear in a matter of months. Industrial settings handle the process much faster and more thoroughly than casual home setups. That means a city with a good organics composting program could see PPC breaking down effectively, but regular landfills or your backyard are not such promising spots.

Marketing Hype Versus Real-World Outcomes

A label saying "biodegradable" usually skips over the messy reality of sorting, collecting, and processing waste. Just because PPC can biodegrade under the right conditions doesn't mean it always does. Eco-certification standards like ASTM D6400 or EN 13432 set strict rules requiring plastic to break down in a commercial composting facility within a few months. PPC passes those tests more often than not, but only when processed properly.

Policymakers, cities, and companies all play a role. Without the right collection bins, PPC ends up in landfill, behaving nearly like conventional plastics. If communities adopt organics recycling programs and teach residents what goes in each bin, actual rates of PPC breakdown go up. I’ve spoken to waste managers who say nearly half of all compostable plastic ends up getting pulled out as trash because of poor sorting.

Charting the Path Forward

Swapping every piece of plastic for PPC won’t fix bigger waste problems on its own. Still, encouraging composting infrastructure and green chemistry research could set the stage for real change. Composters willing to take these materials need more support from public investment, and packaging designers should be upfront about what their products actually become after tossing. As someone who’s watched kids unwrap birthday toys, leaving behind an armful of plastic wrap and containers, I know these choices add up. Individual actions matter, but the decisions made by industry and government count for even more.

Getting Real About Storage Conditions

Polypropylene carbonate, or PPC, doesn’t love surprises. It has a way of inviting trouble if people get careless about temperature and humidity. Most chemical storage nightmares start with heat and moisture. Leave a sack of PPC resin sitting near a steam pipe or a sun-baked loading dock, and the product ends up clumping together or forming odd, degraded bits nobody wants to run through an extruder. At the plant years ago, we learned to keep PPC barrels in a cool, shaded area—out of direct sunlight, with as steady a temperature as the building could manage. Storms and hot spells moved fast, but keeping day-to-day temperatures somewhere below 30°C saved us a lot of headaches. Shelf life shortened if the temperature drifted above this mark, especially in humid months. Moisture can trigger hydrolysis, and you end up sweeping up sticky, unusable powder from the floor.

Pick the Right Containers and Watch the Air Quality

Simple storage bins don’t cut it with PPC. Polyethylene-lined steel drums or high-density polyethylene containers work best. Bags aren't enough; I’ve seen too many thin sacks punctured or torn during delivery. Once even a little air sneaks in, the polymer can take on water from the atmosphere, turning what started as workable material into a lumpy mess. We always covered opened containers right after use. Even on busy days, folks resealed containers before they even thought about their next step. Taking shortcuts meant losses—not just on the books, but in processing delays and wasted resources. People talk about “air quality” like it’s just a line in a standard operating procedure, but keeping dust out does more than protect a batch. It protects everyone who works with it. PPC dust irritates the nose and lungs if left unchecked, so good ventilation belongs on every checklist.

Keep Compatibility and Safety in Mind

There’s a temptation to use whatever happens to be handy around a warehouse. With PPC, that attitude lands workers in hot water, fast. Some solvents degrade PPC even at room temperature—acetone and strong acids come to mind—so the chemical shouldn’t sit near cleaning supplies or leaking containers. In my own experience, a leaky can of solvent once contaminated an entire storage rack. It cost us a lot to scrap those materials and clean up the mess. Companies might skip safety sheets for “simple” plastics, but PPC isn’t just plastic; its makeup makes it more sensitive to its environment than people think.

Minimize Transfers and Label Everything Clearly

Every extra transfer between containers increases the chance something goes wrong—spillage, moisture, foreign material, even mix-ups. Instead, draw directly from original packaging in small, managed amounts. If a transfer is necessary, use dedicated, well-marked bins. Proper labeling isn’t just a bureaucratic step; it’s what stops confusion during busy shifts. In my shifts, I’ve seen operators reach for the wrong drum more than once, especially in cluttered spaces. Mistakes like that can ruin batches or trigger recalls. Smart companies train everyone, from temporary workers to shift supervisors, to check labels—every time.

Solution: Accountability Throughout the Chain

Companies want more than long shelf life—they want reliable, safe, and traceable material. I’ve watched lines run smooth or stall based on how seriously people took the small steps: temperature checks, seal inspections, labeling routines. Solutions don’t lie in bigger budgets or fancier technology. They show up in daily habits. Setting up clearly marked areas, holding walkthroughs for new staff, appointing someone to check logs at the end of a shift—little things create safer plants and better products. Storage and handling might sound dull, but get it wrong once, and the lesson sticks. For PPC, safeguards and smart routines lead to fewer accidents, cleaner runs, and lower waste. That keeps everyone, from operators to end users, a little safer.

Why Polypropylene Carbonate Matters

Polypropylene carbonate, a kind of aliphatic polycarbonate, stands out in conversation about greener plastics. Its story starts with a simple combination—carbon dioxide and propylene oxide. The reason more chemists and manufacturers talk about it isn’t only curiosity about its structure. For people worried about sustainability and real environmental impact, this material grabs attention. Some companies tout it for helping cut down on raw petroleum-based products. As someone who has seen plastic waste pile up where it shouldn’t, that claim carries real weight.

Physical Properties You Notice in Daily Life

The feel and strength of a material make a bigger impression than any technical sheet. Polypropylene carbonate (PPC) sits somewhere between rigid plastic and flexible film. Its glass transition temperature usually lands between 25°C to 45°C. That keeps PPC just a bit softer than typical polystyrene, so it doesn’t get brittle in cool rooms, yet won’t keep its shape above standard boiling water. Fingernails can make marks, but the material won’t shatter or snap under normal stress.

PPC melts at moderate temperatures, usually around 220°C. This lets manufacturers mold or extrude it using equipment already in use for more common plastics. In my experience, that’s key. Companies avoid reshuffling production lines for every new eco-friendly product—cost and time matter for everyone, from plant manager to warehouse loader. PPC’s density, hovering around 1.18 g/cm³, also matches many plastics, so there isn’t a lot of surprise when it shows up in mixed recycling streams.

Transparency brings another real advantage. Thin sheets let through light, so PPC fits right into packaging where people want to see what’s inside—food trays, clear boxes, window envelopes. It also holds together well in thin films, so it often appears as a clingy wrap, keeping dry goods sealed up.

Chemical Properties and What That Means for Use

At the molecular level, PPC resists water pretty well. Unlike starch-based plastics, it doesn’t dissolve or fall apart during short-term exposure to humidity. Still, leave it soaking for a week or two, and hydrolysis slowly chews up the chain, especially in hot, acidic, or basic water. Every year, I see questions come from packaging plants: “Can we use PPC for this soup container?” The answer depends on shelf life and temperature.

PPC fares poorly against strong solvent mixtures. Simple alcohols might not break it down, but acetone or aggressive esters cut its strength and make it sticky. In that sense, don’t expect to use PPC for bottles holding industrial cleaning chemicals or potent nail polish remover.

One standout is the way PPC responds to compost and landfill environments. Under industrial composting, it breaks down over several months, thanks to those carbonate links in the chain. Microbes love the stuff in just the right heat. Nobody claims it vanishes overnight, but it decomposes much faster than most polyolefins or PETs. I’ve had a few community groups ask about running small compost tests—that’s something worth doing if you want proof instead of promises.

How to Tackle the Challenges

PPC doesn’t fill every niche on its own. Heat resistance needs a boost if hot-filling or dishwasher safety is on the table. Blending with other biodegradable materials smooths out some weaknesses. Labs and companies have found success adding polylactic acid or talc, toughening up the mix against sagging or melting. Regulatory approval also remains a crucial checkpoint. Everything that touches food or medicine gets extra scrutiny, so transparency and rigorous testing show up alongside technical data in any smart discussion about new PPC uses.

For local governments and buyers, it makes sense to ask suppliers questions about shelf life, composting conditions, and chemical exposure. Honest labeling and better public education go a long way. Polypropylene carbonate brings practical opportunities to stretch the useful range of bio-based plastics, and solutions grow better when tested out in real markets, not just lab benches.

Understanding Polypropylene Carbonate in Food Packaging

Polypropylene carbonate (PPC) has caught the eye of manufacturers looking for new ways to keep food fresh. It’s a biodegradable plastic, made by combining carbon dioxide with propylene oxide, which sounds greener than many fossil-fuel options. It shows up in films, coatings, and rigid containers, giving food packaging new flexibility and strength. Anyone shopping for groceries today sees thousands of packaged goods, making the question of safety more than just scientific curiosity. It’s about what goes on dinner tables every night.

Assessing the Safety Record of PPC

No one wants harmful substances touching their food. As a parent and longtime label-reader, I care about what could move from packaging into meals. Research has dug into this, checking how PPC interacts with food and whether anything leaches out. The data tells us that PPC holds up better than many plastics under normal food-service conditions. Regulators in the European Union and several Asian countries recognize PPC for certain food-contact uses, based on migration tests and toxicity studies.

Scientists have run irritation and acute toxicity tests—both in animals and on cultures. Results consistently show low risk, as long as manufacturers stick to the approved grades and keep additives in check. The U.S. Food and Drug Administration doesn’t have a sweeping approval in place, but some specific PPC uses have passed review. Anyone with experience in packaging knows how strictly these barriers are enforced.

Concerns About Additives and Degradation

While the plastic itself stands up to scrutiny, attention shifts to additives. To make PPC workable, manufacturers sometimes add plasticizers or stabilizers. These extras can pose questions, especially if the formulas aren’t clear. In the USA, food packaging regulations lay out what can be used and in what amounts, with standards set to limit migration of any substance into food. Still, watchdog organizations push for more transparency around what goes into the finished material.

Heat, sunlight, and handling can break down many plastics. PPC, being biodegradable, could degrade faster than traditional polymers, which appeals to anyone thinking about environmental impact. At the same time, there's concern about breakdown products, especially if packaging sits on a shelf for months. Most studies so far suggest that the main byproducts—carbon dioxide and propylene glycol—don’t cause harm at the expected levels. Still, the nature of scientific inquiry means more long-term data always helps.

Improving Safety and Consumer Trust

The safest package comes from a transparent process, where suppliers publish their ingredient lists and provide clear data about migration, toxicity, and environmental fate. Brands committed to public health go beyond legal minimums to test for all possible contaminants. I value being able to scan a QR code or website and see lab results, not just marketing pitches.

Regulators need to keep reviewing new data as the science changes. Independent labs, consumer groups, and universities all play a role, making sure that the promise of green plastics doesn’t hide risks. Certification programs, clear labeling for compostability, and third-party audits push the industry to keep improving.

Looking Ahead

PPC brings real promise for safer, lower-impact food packaging. Staying safe depends on rigorous ingredient checks, honest labeling, and constant monitoring of new findings. Choosing trustworthy products comes down to recognizing both the science and the systems behind it, putting health and safety ahead of hasty innovation.