Neopentyl Glycol: A Critical Review of Its Journey, Uses, and Future

Historical Development

Neopentyl glycol’s route into modern industry started back in the 1930s when chemists explored branched aliphatic diols as alternatives for improved stability in resins and plasticizers. Researchers found that this unique glycol gave their resins a major performance boost—improving weather resistance, flexibility, and durability over time. Once DuPont and other chemical giants picked up on these capabilities, neopentyl glycol soon anchored coatings and plastics lines through the middle of the twentieth century. Decades later, the material still features heavily in industrial chemistry, standing as testament to how core organics can push technology forward more than any corporate slogan or marketing splash ever will.

Product Overview

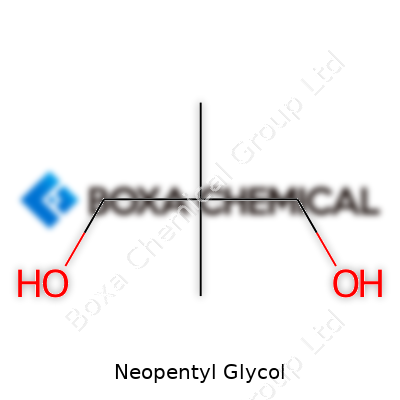

Every time manufacturers put neopentyl glycol on the product list, they eye a combination of chemical stability and convenience. Its structure, carrying a pair of terminal hydroxyl groups on a quaternary carbon, forces the molecule to resist unwanted reactions, which lets paints and polyesters last longer. Warehouses often stock it as a white, crystalline powder or granule that stores at room temperature for extended periods. Chemists get a kick out of its sheer reliability—a major reason companies keep locking in their supply contracts year after year. Its CAS number, 126-30-7, gets referenced in purchase orders and regulatory filings from Boston to Shanghai; few specialty polyols see this level of global recognition among technical buyers.

Physical & Chemical Properties

Stick a thermometer in a jar of neopentyl glycol and it melts around 128°C—well above regular glycol, so formulators use it when high process temperatures come into play. The powder dissolves with some effort in water, but it loves organic solvents, especially alcohols and esters, which broadens the tricks you can do with it in a bench lab. Its boiling point falls north of 200°C, which cuts down evaporation during mixing or curing. Usually, the sharp, odorless crystal form signals top-end purity; anything less turns up fast in quality tests, and few processors will tolerate even faint yellowing or contamination.

Technical Specifications & Labeling

Production teams routinely check the purity by measuring melting point, water content, and acidity. Most end users demand a product purity topping 99.5%, with water content below 0.5%. Packaging comes in moisture-resistant bags or drums, emphasizing shelf life and consistent granule size. Labels show the material safety data, batch number, production date, and warnings in line with global hazard communication standards like GHS. Shipping documentation includes the UN number 2811, underlining proper handling for bulk transit—nobody wants an accident because a supplier cut corners on paperwork or signage.

Preparation Method

Factories synthesize neopentyl glycol by hydrogenating hydroxypivaldehyde, itself a product of formaldehyde and isobutyraldehyde reacting together via aldol addition. The reaction creates a tertiary carbon core, blocking pathways that would otherwise lead to oxidative or thermal breakdown. Setups rely on pressurized hydrogen, nickel or copper catalysts, and careful heat management. Any slip in parameters tanks the yield or triggers byproduct formation. Engineers refine the steps for energy efficiency and to wring out as much product as possible from every batch—waste streams mean wasted profits in chemical manufacturing.

Chemical Reactions & Modifications

Mix neopentyl glycol with acids and you get a broad array of esters, each suited for industrial plasticizers or synthetic lubricants. Under controlled dehydration, it yields cyclic ethers that find their way into advanced coatings. The molecule resists oxidation far better than standard glycols, thanks to the shielded central carbon; this trait improves the longevity of final goods, whether you’re talking outdoor signage or weatherproof furniture paints. Chemists exploring new polyesters or alkyd resins turn to this glycol when durability can’t be sacrificed for flexibility or price.

Synonyms & Product Names

Common names abound for neopentyl glycol, with “2,2-dimethyl-1,3-propanediol” leading technical documents. Traders often abbreviate to NPG for ease. Branding varies between producers—Eastman markets it as “Eastman Neopentyl Glycol,” BASF just calls it NPG, while smaller Asian suppliers roll out trade names tailored for regional markets. Despite this range in presentation, any qualified chemist can spot real NPG by structure and performance, not just the packaging artwork.

Safety & Operational Standards

Working with neopentyl glycol doesn’t carry the dangers found with some older glycols, but standard chemical hygiene still applies. Lab technicians wear gloves and goggles due to mild irritancy of the powder on skin and eyes. Dust control matters during transfer and weighing operations; airborne particles above 10 mg/m³ cause discomfort and mess. Respirators come out in case a spill can’t be swept up dry. Safety data sheets stress that, in case of fire, responders should reach for foam or dry chemicals—water might spread the fire involving other volatile components. Both OSHA and European Union regulations spell out occupational exposure limits and transport guidance; smart plants stick tightly to these.

Application Area

Polyester resins, synthetic lubricants, and alkyd coatings pull more than their fair share of neopentyl glycol output every year. Outdoor paints and plastics last longer when this compound makes up part of the backbone, fighting off the yellowing and brittleness brought by relentless sun and rain. Automotive manufacturers lean on NPG-modified resins for bumper coats and trim, looking for a finish that survives both city grime and highway salt. Some specialty polyurethanes and hydraulic fluids also depend on it for improved resistance to breakdown. In everyday life, the staying power of road signs and brake fluids owes a quiet debt to this unassuming diol.

Research & Development

Universities and industrial research teams continue to dig into the chemistry of neopentyl glycol, hoping to uncover even more robust polyester variants or safer, more eco-friendly resin systems. Green chemistry pushes have triggered waves of research into bio-based alternatives, though replicating the heat and oxidation stability of the original rarely comes easy. Firms like Covestro or Mitsubishi Chemical support academic partnerships to unlock new applications, particularly where stricter REACH or EPA rules squeeze older plasticizers and glycols off the shelf. The high interest in renewable feedstocks hasn’t dropped demand for performance—if anything, it’s raised the bar for what a “green” option has to deliver.

Toxicity Research

Animal studies and exposure monitoring repeatedly show that neopentyl glycol has low acute toxicity across skin, ingestion, and inhalation pathways. Regulatory agencies have reviewed the effects on humans and found no evidence of carcinogenic potential or genetic harm at operational doses. Chronic exposure, as seen in poorly ventilated facilities, sometimes leads to mechanical irritation rather than systemic toxicity—a bonus over more reactive organics. Research labs keep a close eye on high-dose effects to make sure evolving manufacturing methods don’t change the safety profile, especially as nanoparticle forms and new ester blends emerge in downstream sectors. Ultimately, robust workplace controls and spill response training keep the risks manageable on the industrial floor.

Future Prospects

Consumer appetite for greener chemistry and tougher materials keeps neopentyl glycol’s market outlook buoyant, despite headwinds from regional regulation. Producers eye shifts toward bio-based synthesis routes to cater to clients avoiding fossil-derived intermediates, even if the bio-pathway currently runs more expensive than the old-school petrochemical approach. Coatings and engineering plastics demand won’t fall away soon, and nimble producers who jump on trends like waterborne paints or recyclable composites will grab market share. New functional derivatives offer yet-untapped possibilities—think smart coatings that heal cracks, or tougher plastics for electric vehicle housings. Chemistry won’t solve every challenge overnight, but products like neopentyl glycol keep pushing the whole sector forward, one reaction at a time.

What Is Neopentyl Glycol and Why Do Manufacturers Care?

Neopentyl glycol, or NPG, shows up all over modern manufacturing. At its core, NPG is a simple chemical, but it plays a big part in making materials that last longer and resist tough conditions. I’ve bumped into NPG’s impact in odd places: car paint that doesn’t fade in the summer sun, furniture coatings that don’t scratch when the grandkids go wild, and even the durability of everyday plastics.

Quiet Strength in Paints and Coatings

Most people don’t think of the chemicals inside the shiny finish on their car or the glossy kitchen cabinet. NPG gives those coatings the backbone needed to shrug off sunlight, moisture, and chemical spills. By promoting high cross-linking in resins, NPG helps block the slow creep of water into a paint layer, which means no bubbling or peeling, even after years of weather. In my own garage, there’s a set of old patio chairs that hold up every summer without chipping; coatings with NPG can take credit for part of that toughness.

Polyesters for the Real World

Polyester resins owe a lot to NPG. It’s a building block in synthetic resins, giving them flexibility without making them soft. I remember working with a cabinetmaker who tested different laminate countertops. The ones using NPG-based polyesters resisted stains and could handle dropped coffee mugs better than the budget options. That matters for busy families or restaurants, since durability makes for fewer repairs and lower costs over time.

Staying Solid Under Heat and Pressure

NPG isn’t just about keeping things pretty; it holds up when heat and stress would wreck other materials. Think of electronics or car parts exposed to engine heat. Polyesters built with NPG handle thermal cycling well, so they don’t crack or break down. Cars, fridges, and washing machines need these advantages if they’re going to last years without parts giving out. In fields like renewable energy, where equipment sits in the sun or rain for decades, every bit of chemical stability matters.

Dealing with the Environmental Side

Those manufacturing benefits don’t erase real environmental worries. Producing NPG relies on petrochemical feedstocks. That’s a reminder that most durable, lightweight plastics still come with an environmental trade-off. Some new factories invest in safer processing and recycling, which helps a bit. For buyers, there’s power in choosing products that last longer, since longer lifespans cut down on overall waste.

Room for Safer Chemistry

NPG is not considered a major health risk when used responsibly, but I’ve found that good ventilation and protective equipment always matter, especially in small shops or DIY projects. Regulatory agencies keep an eye out, as long-term effects from any chemical deserve close attention. Industry is also looking at safer, bio-based alternatives, but for now, NPG holds its ground in plenty of critical applications.

Concrete Innovations with Real Payoff

In the end, NPG makes a real difference in the world I see and touch. Without it, we’d have less reliable coatings and more waste. Its story plays out quietly—in smoky kitchens, busy roads, and neighborhood parks—where built-to-last matters. The next step means balancing performance with new chemistry solutions. For now, NPG remains a quiet but crucial part of the products that surround us.

Shape and Structure Matter

Neopentyl glycol looks unassuming—just a white, crystalline solid—but underneath, its unique structure packs a punch. It’s built from two alcohol groups attached to a central carbon atom, which gives it unusually high stability. This special structure keeps it from breaking down easily, especially in harsh industrial conditions where heat or strong chemicals would usually do damage.

Stability That Counts

You see this stability in action during the making of resins, coatings, and plastics. In industries I’ve worked with, finding an ingredient that doesn’t fall apart when exposed to moisture or oxygen means products last longer. Most regular glycols can yellow or lose strength over time, especially outdoors. Neopentyl glycol steps up where others fail, adding years to the life of surface coatings and plastic products by fighting off UV rays and resisting destructive reactions.

Improved Hardness and Flexibility

Factories aren’t just searching for toughness; they want versatility too. With this glycol in the mix, you get both hardness and flexibility. I’ve seen paint manufacturers lean on this quality. When used in automotive coatings, it helps give a lasting, glossy finish, but it also bends instead of cracking when a car door gets dinged. It supports a smooth surface while holding up to the punishment of daily use.

Water Resistance at Its Best

In the real world, water gets everywhere. Any level-headed engineer sees water resistance as a must for almost anything left outside. Neopentyl glycol creates a barrier that keeps water from creeping in, which helps explain why it works for weatherproof coatings and adhesives. Wooden window frames coated with resins using this glycol won’t swell or rot as quickly. Adhesives with neopentyl glycol handle humidity better, keeping furniture joints from loosening.

Ease in Processing

Chemical plants need ingredients that melt and blend predictably. This glycol melts at a comfortable 130°C, which fits most manufacturing lines without special gear. It dissolves smoothly into common solvents, making it easier to mix with other chemicals to produce foams, polyesters, or lubricants. Consistent, predictable melting means less downtime on the factory floor and fewer production surprises.

Low Toxicity and Safer Use

Health and safety never take a back seat in any modern operation. Reports from regulatory bodies like the European Chemicals Agency point to low toxicity for neopentyl glycol. This gives peace of mind when it gets used in areas like food packaging and children’s toys, where strict safety standards rule. Workers also face fewer hazards during routine handling compared to riskier chemicals.

Environmental Impact and Potential Improvements

Environmental regulations keep getting tighter on plastics and coatings. Neopentyl glycol earned trust partly because it resists breaking down into harmful byproducts. Still, the process to manufacture it often draws on raw materials from non-renewable sources, and that deserves real discussion. Pioneers in the chemical industry are exploring routes to make this glycol with greener feedstocks. Pushing for more sustainable production loops would cut the carbon footprint and make a solid performer even better for the long haul.

Summary

From what I’ve seen across different fields, neopentyl glycol brings durability, flexibility, and safety to finished goods. As long as the industry keeps up efforts to clean up production, this glycol will keep its role as a dependable, future-ready building block.

Everyday Encounters with Industrial Chemicals

People cross paths with chemicals daily, even if few folks think about it. Take neopentyl glycol, a chemical you’ll spot in everyday goods like paints, lubricants, and some plastics. Its role in industry looks straightforward on paper, but the question about risk is worth asking, since a name with “glycol” in it might set off alarm bells for anyone who remembers old antifreeze scares.

Understanding What’s in the Bottle

Neopentyl glycol comes out of factories as a white, odorless solid. It doesn’t vaporize easily, which means breathing it in takes real effort or a serious spill. Unlike some glycols that cause trouble like ethylene glycol, neopentyl glycol can’t tempt pets or kids with a sweet taste since it doesn’t hang around in liquid form outside a heated factory.

Digging Into Health Effects

Skin or eyes hate contact with most industrial powders and neopentyl glycol fits that pattern. Workers might get rashy hands, redness, or even an itchy throat if they stir up enough dust. Anyone unlucky enough to splash it in their eyes can expect a fierce sting, though most cases clear up fast and aren’t life-threatening. Swallowing a large scoop by accident sounds like a rare event, but animal studies back up the idea that it’s not extremely toxic through that route either. Most regulatory agencies don’t slap a strong hazard label on neopentyl glycol for basic contact, though they always say don’t eat the stuff.

Workplace Worries and Proper Precautions

The safety conversation picks up in places where workers handle it daily. Dust floating in the air threatens lungs, just like flour or wood dust. Some countries ask factories to track air levels so no one ends up wheezing or coughing as a regular part of the job. Proper gloves, goggles, and masks stop those problems up front. Spills clean up with a sturdy industrial vacuum or a mop, not a home broom. Experience working around chemicals says that being sloppy about storage or clean-up turns a minor chemical into a mess.

Environmental Considerations

No chemical stays inside four factory walls forever. Some neopentyl glycol seeps out in wastewater or heads for the landfill. Once in the wild, it breaks down fairly quickly—bacteria feast on it, meaning it doesn’t poison streams or soil long-term. Fish and wildlife dodge serious harm since it doesn’t hang around or build up in food chains. Official reports suggest it ranks far safer than plenty of the solvents and additives out there that have caused headline disasters.

Smart Choices for Industry and the Public

People deserve to know what flows through their neighborhoods and what gets into the products they use daily. Workers should always have access to clear safety labels and protective equipment. Industry can keep risks down with regular air monitoring and good hygiene rules. Clean, labeled storage and a strong spill response plan make sure neopentyl glycol doesn’t become the kind of chemical that draws lawsuits and angry headlines. For the home consumer, risk drops close to nothing—common household use hardly puts neopentyl glycol in arms’ reach.

The Importance of Staying Vigilant

Too many chemicals gained a safe-sounding reputation until years down the line showed otherwise. Trust builds on strong science, worker health reports, and honest reporting from manufacturers. Regulators review these chemicals on a regular schedule and update guidelines if new science comes to light. Until big evidence says otherwise, neopentyl glycol doesn’t belong with the truly hazardous crowd. That said, taking shortcuts with chemical handling invites the very risks history has taught us to avoid.

Why Safe Storage Really Matters

Neopentyl Glycol doesn't usually ring alarm bells like some chemicals, but that’s not a green light to go careless. Anyone who has watched simple oversights turn into costly incidents knows this. It’s a white, crystalline solid that finds its way into resins, coatings, and lubricants. You can find it stacked on shelves in plants and labs everywhere. Even then, it can irritate the eyes, skin, or lungs if you come into direct contact, so it’s worth giving the safe storage topic some real thought.

Smart Storage Starts With the Basics

In practice, neopentyl glycol needs a sealed container, just like sugar in your kitchen. Moisture turns it lumpy and messy, and over time, even a tiny amount of water affects the quality for sensitive applications. Dry storage isn't up for debate; it’s a non-negotiable. People often forget how heat can quietly ruin stock, but leaving the drum somewhere warm invites clumping and melting—nobody wants to chip away at a sticky brick before work even begins. Ambient temperature, cool but not freezing, keeps it in ideal condition. A temperature range between 2°C and 8°C generally works well.

Containers should resist corrosion and avoid metal parts that react. A drum left open is an accident waiting to happen, because airborne dust or dampness turns a reliable shipment into rejected material. My years in facilities management prove that poly-lined drums offer the most reliable protection, and good labeling prevents the mix-ups that lead to wasted time and paperwork.

Handling Isn’t Guesswork

Even though neopentyl glycol is safer than many industrial chemicals, gloves and goggles are not optional. Spills around loading bays almost always come from people rushing the transfer—whether scooping powder into a feeder or moving bags by hand. The few seconds saved never balance out against the mess and risk. Respirators often sit unused, but once the dust rises, the throat and sinuses take the hit. Keeping basic personal protective gear within reach—right at the storage area—turns good habits into daily routines.

Some folks forget about static discharge. This powder can generate static, especially in dry conditions. Grounding the equipment before transfer stops sparks. In small shops, this might feel like overkill, but the first minor fire means policies change overnight.

Why Oversight Doesn’t Outgrow Its Purpose

Even after years working with chemicals, you start to see how procedures that seem restrictive exist to keep the workflow, health, and integrity of products in check. It’s easy to slack with something that hasn’t caused problems—until one slip requires hours cleaning a spill or filling out incident reports.

Safety data sheets can feel like extra paper, but they help staff new and veteran stay on the same page. Giving refresher training every few months doesn't just fill seats; it cuts mistakes and strengthens the safety culture. Inventory checks catch leaks or damaged packaging before the problem spreads. It’s about more than regulation—it’s part of keeping people and shipments intact.

Simple Upgrades Pay Off

Automatic ventilation in storage rooms, spill trays beneath shelves, and no-skid floors take only a little up-front investment, but prevent major headaches. Small companies sometimes underestimate the return on these changes. Emergency wash stations in sight, not behind a locked door, reduce response time and can turn a bad day into a minor inconvenience.

Neopentyl glycol may not appear on the list of headline-grabbing hazards, but treating it with respect—the same respect given to more dangerous chemicals—ensures long-term safety, product reliability, and peace of mind for the folks on the ground.

Building a Better Coating: The Backbone of Paints and Resins

Walk through any city and take in the colors coating bridges, cars, or playgrounds. That durable, weather-resistant finish owes a lot to Neopentyl Glycol, known in short as NPG. Most modern paints and coating resins count on it for flexibility, gloss, and the power to stand up to rough sun or a hard rain. NPG brings stability to polyester and alkyd resins, the key ingredients in many surface coatings. These qualities don’t just help paint look good; they help steel and wood last longer, slowing down rust and rot. Roads crews, home builders, and auto shops rely on this toughness every day. If a truck rolls through winter slush and keeps its color, there’s a strong chance NPG played a role.

Automotive Innovation: Staying Ahead of Heat and Pressure

Inside the engine bay, conditions get harsh. Gaskets, paints, and composite panels in cars can’t give up under constant vibration or heat. NPG-based polyester resins deliver components that don’t crack or warp. Molded plastic car parts and heat-resistant finishes hold their shape through summer traffic jams and winter freeze-thaws. As cars add more electronics and lightweight plastics, the need for materials that won’t disappoint grows. Manufacturers turn to blends that use NPG’s unique chemical backbone to keep engines, body panels, and even battery housings robust and reliable.

Electronics: Keeping Devices Safe and Efficient

Smartphones, laptops, smart TVs – nearly every screen or circuit relies on plastics that resist heat and shrinkage. NPG shows up inside printed circuit boards as well as component housings and protective films. These parts have demanding jobs: they prevent short-circuits, shield against dust, and fend off moisture. In today’s world, where electronics double as lifelines and workhorses, a sudden housing crack or insulation slip causes headaches for millions. NPG-based plastics have earned their place because they power results, not excuses.

Molded Plastics: Versatile and Tough

I’ve spent years tinkering with home appliances and noticed how handles, buttons, and housings keep their strength after years in a steamy kitchen or cold garage. That long life comes from NPG’s chemical structure—it provides balance between flexibility and rigidity. Water filters, fridge components, power tools, even kid’s toys can hold up under stress thanks to toughened resins enhanced with this ingredient. The ability to balance cost with long-term reliability keeps NPG at the center of modern manufacturing lines.

Adhesives and Lubricants: Holding Things Together

Construction doesn’t pause for wet days or freezing mornings. Reliable adhesives used in flooring, tilework, or even outdoor signage use NPG to create bonds that won’t fail when exposed to water or temperature swings. Specialty lubricants, especially for those tough tasks like running textile machinery or farm equipment, perform better with certain NPG esters that reduce oxidation and breakdown. These products help keep businesses running and minimize costly downtime for repairs.

Looking Forward: Pushing for Safer, Greener Chemistry

Every year, teams in industrial labs try to lower volatile organic compounds in paints and fine-tune resins for recycling. NPG offers an advantage: it creates chemical bonds that produce fewer emissions and last longer, which matters for air quality and landfill pressure. More factories now choose NPG-derived polyesters to meet stricter rules and answer calls for sustainable design. Safer paints and high-performance plastics are no longer luxuries—they’re becoming basic expectations, and NPG will be sticking around for the long haul.