An In-Depth Look at Isobutyraldehyde

Historical Development

The story of isobutyraldehyde traces back to breakthroughs in organic chemistry in the late 19th and early 20th centuries, where research into aldehydes gained steam as scientists worked to decode the behavior of simple carbonyl compounds. This chemical’s manufacture soon scaled up after World War II, as rising demand for specialty chemicals pushed manufacturers to build more robust processes. Early on, traditional synthetic methods such as hydroformylation of propylene laid the foundation for today’s industrial preparation methods. Production of isobutyraldehyde proved key in developing various intermediates, guiding advances in plastics, pharmaceuticals, and flavors during the expansion of the chemical industry in many countries.

Product Overview

Isobutyraldehyde fills a critical niche in the chemical world. As a colorless, flammable liquid, it plays a middleman’s role, linking upstream propylene-based chemistry to key downstream products. Its manufacturing supports value chains for amino acids, plasticizers, crop protection chemicals, and food flavorings. Industries across the world draw on isobutyraldehyde as a raw material. What stands out from decades of observations is the way this compound adapts to new industrial challenges, finding use in surprising ways once chemists grasped its reactivity.

Physical & Chemical Properties

With a boiling point close to 63 degrees Celsius and a melting point near -65 degrees Celsius, isobutyraldehyde comes with low viscosity and a sharp, pungent odor. Its low density and volatility demand proper ventilation in working environments. It dissolves in typical organic solvents but resists mixing with water due to its relatively compact structure, driving separation needs during purification. Its molecular formula, C4H8O, keeps it light and maneuverable in various chemical steps. Because of the reactive aldehyde function, storing isobutyraldehyde calls for cool, inert conditions to limit unwanted polymerization or oxidation.

Technical Specifications & Labeling

Regulatory bodies such as the European Chemicals Agency (ECHA) and the US Occupational Safety and Health Administration (OSHA) require accurate labeling for isobutyraldehyde. I’ve seen how manufacturers must declare the substance’s CAS Number (78-84-2), purity—usually above 98% for industrial uses—along with the presence of known impurities like isobutanol and acrolein. Storage instructions emphasize protection from sunlight, airtight containers, and locations away from oxidizers and acids. Safety Data Sheets spell out hazard classes, emergency action, and personal protective gear recommendations. Clear technical standards help minimize risk during bulk storage, transport, and handling, which strengthens trust between suppliers and end users alike.

Preparation Method

Today’s main commercial method relies on hydroformylation, often called the oxo process. In this process, propylene reacts with hydrogen and carbon monoxide, often in the presence of a rhodium or cobalt catalyst, to yield isobutyraldehyde alongside n-butyraldehyde. This approach provides good selectivity thanks to tuned parameters—pressures up to 25 MPa and strict temperature control, which keep yields high and waste minimized. Some small-scale lab syntheses follow alternative routes, like reduction of isobutyronitrile or oxidation of isobutanol, serving specialty applications where purity and selectivity are more important than raw output.

Chemical Reactions & Modifications

Once available, isobutyraldehyde serves as a springboard for further transformation. The aldehyde group reacts readily with many nucleophiles, which fuels applications in producing isobutanol by hydrogenation—a route heavily used for solvents and feedstocks. It enters aldol condensations to construct more complex molecules, crucial in pharmaceutical and material synthesis. Oxidation yields isobutyric acid—a key ingredient in some pesticides and food additives. Various Grignard reactions, reductive amination steps, and acylations build new molecule classes harnessing isobutyraldehyde’s reactive backbone.

Synonyms & Product Names

Chemists deal with a landscape of names for the same compound, creating confusion unless all parties pay attention. Other references for isobutyraldehyde include 2-methylpropanal, isobutanal, and trimethylmethanal. Older literature, especially from the first half of the 20th century, preferred 2-methylpropionaldehyde. Trade names rarely show up since this material functions as a feedstock, but accurate synonym lists serve regulatory filings and safety data systems. My own experience chasing down synonyms in database searches underlines the value of clear, harmonized naming conventions.

Safety & Operational Standards

Working with isobutyraldehyde brings both fire and health risks. Its low flash point, strong vapor pressure, and low ignition energy mean every site using it must take explosive atmosphere safety seriously. Inhalation of vapors can irritate eyes, skin, and airways, and long-term exposure may affect the nervous system. Standard operating procedures call for strict ventilation, gas detection, antistatic measures, and regular worker training. I’ve helped set up chemical warehouse ventilation that moves above the vapor layer and uses local exhaust at points of use. Good practice builds in spill containment and rapid responder protocols for leaks or exposure.

Application Area

Isobutyraldehyde’s downstream value shines brightest in the flavor and fragrance industries, where transformation to isobutanol offers fruitlike, buttery notes. Manufacturers of plasticizers turn to isobutyraldehyde in building up pivalic acid esters, adding flexibility to vinyl-based materials. It forms a vital part in amino acid synthesis, like valine and leucine, which reach the feed supplement and pharmaceutical sectors. Pesticide makers draw on its presence in isobutyric acid, while specialty resins and coatings rely on its role in constructing branched monomer units. These overlapping uses fuel steady demand, with each sector pushing for reliable supply and high purity.

Research & Development

Current R&D activities focus on greener, more sustainable production routes for isobutyraldehyde. Academic groups push for biotechnological methods—using engineered microbial strains to generate aldehydes from renewable sugars, which could lower reliance on fossil fuels and reduce process emissions. Researchers in catalyst design work on increasing hydroformylation selectivity, minimizing waste aldehyde streams, and tightening product specifications. Digitalization in process monitoring lets operators keep tighter control over individual reactor runs, leading to safer and more consistent product outcomes. Trade association reports show growing interest from both startups and established industry players.

Toxicity Research

Toxicologists scrutinize isobutyraldehyde’s health effects in both acute and chronic exposure models. Studies document eye, skin, and respiratory irritation at concentrations exceeding occupational safety limits. Rodent trials highlight organ-specific toxicities and set out no-effect levels that guide limits in workplaces. Acute toxicity—measured by LD50—remains low relative to many industrial chemicals, but concerns about potential neurotoxic impacts prompt regular monitoring in production sites. Emerging research looks to uncover long-term health effects, supporting ongoing risk assessments and regulatory reviews.

Future Prospects

Ongoing shifts in materials science and green chemistry keep isobutyraldehyde in strategic focus. Trends point toward rising demand in high-value consumer products and specialty chemicals. Sustainability goals drive both government and private investment into lower-carbon routes, such as bio-based hydroformylation processes and improved recycling of process streams. Companies adopting stricter product stewardship systems stand to win customer confidence and regulatory clearance. As long as the need for versatile aldehyde intermediates persists, investment in both manufacturing excellence and safety will keep isobutyraldehyde relevant in both legacy and emerging industry sectors.

Getting to Know Isobutyraldehyde

Walk into any factory that makes paints, plastics, or even flavors, and chances are you’ll find isobutyraldehyde involved somewhere in the process. This colorless liquid comes with a sharp odor, and it shows up where people least expect it—in the ingredients for coatings, the flavors in snacks, and chemical reactions that build industrial products. What’s interesting is how something nobody talks about actually shapes a whole lot around us.

Building Block for Everyday Goods

Factories lean on isobutyraldehyde as a starting point. They use it to produce chemicals like isobutanol and neopentyl glycol. Isobutanol appears in solvents and paints, while neopentyl glycol toughens up resins that keep plastic and paint surfaces smooth and durable. Anyone who’s ever worked a summer painting houses knows you want that finish to stay sharp for more than a year. These ingredients give that resilience.

People in the perfume industry use isobutyraldehyde to create fresh scents. In the flavor world, chemists twist its structure around to mimic fruity and nutty notes. If you’ve tasted banana-flavored candy or a nutty cookie, isobutyraldehyde probably helped give it that kick. These details might sound small, but flavor scientists care about the difference between “just okay” and “this tastes like the real thing.”

Fuel for Industry, Not Just Fragrance

On the factory floor, isobutyraldehyde helps make plasticizers. These plasticizers keep PVC flexible—a big deal if you care about pipes lasting or wires bending without cracking. Manufacturing folks have found that isobutyraldehyde lets them tweak plastics for almost every job, from hospital tubing to car interiors. The material science side isn’t just chemistry, it’s design for real problems people face.

Isobutyraldehyde also takes part in the production of pesticides and herbicides. Those working on modern farms rely on these products to protect crops and keep yields steady. Critics often raise concerns about agricultural chemicals, and people deserve an honest discussion. Regulatory bodies in the US and Europe keep a close watch on emissions and worker safety. I’ve seen strict protocols put in place on plant tours—ventilation, sensors, and worker training all lower risks.

How Safety and Sustainability Factor In

Breathing in isobutyraldehyde isn’t recommended, and spills can be trouble, so chemical engineers pay close attention to safety. I’ve known folks who work with it daily, and keeping up with equipment checks and protective gear is standard practice. Regulations set by agencies like OSHA protect workers, and smart design helps vent and capture fumes before they become a hazard.

More manufacturers look at greener routes these days, choosing processes that cut waste and recycle more raw material. Scientists have started working with renewable feedstocks for making isobutyraldehyde, instead of using only petroleum. This switch isn’t quick, but it matters when whole communities live near factories, and people want both jobs and a clean environment.

Looking Ahead

What sets isobutyraldehyde apart isn’t just what it does today, but how people find smarter ways to use it tomorrow. There’s real potential for safer, more sustainable chemistry. Open conversations between workers, neighbors, and companies help ensure that progress doesn’t come at someone else’s expense.

Understanding the Risks

Isobutyraldehyde doesn’t get much spotlight outside of chemistry and manufacturing circles, but those who work around this clear, pungent liquid know it deserves respect. Even a midsize spill can turn a normal shift into a scramble, so preparation matters. Studies and accident reports point out the irritation risks—not only for skin and eyes, but also for folks’ lungs if vapors get out of hand. The U.S. National Library of Medicine and the European Chemicals Agency both highlight its flammable nature, which puts it on the map for both chemical burns and explosion hazards. Going in prepared can keep teams and labs out of trouble.

Protection That Actually Works

From personal experience in the lab, gloves are your first friend. Nitrile or neoprene gloves stand up better than plain latex. Splash goggles keep the worst of the burns away from your eyes, and chemical-resistant coats or aprons add an extra layer. Don’t trust regular cotton gear—liquid soaks through, and the fumes hang around. After seeing a co-worker forget eye protection once, no one in the room needed to hear another safety briefing—the red, watery eyes and quick trip to the eyewash station said it all.

Always keep the area well ventilated. Fume hoods help, but a backup exhaust system makes a difference if you measure or pour large amounts. Even in industry, relying on just one line of defense brings real risk. Monitoring equipment can pick up unexpected leaks, especially when transferring isobutyraldehyde from storage drums. I’ve seen monitors catch leaks invisible to the nose, so never turn them off.

Fire Hazards Deserve a Plan

You can’t talk about isobutyraldehyde without talking about fire. The flash point sits low, meaning routine heat sources spell danger. No open flames, no hot plates left running; that’s not just a rule, it’s lived experience after a small spill met a spark in a poorly ventilated warehouse—scary, fast, and over before anyone could react. Dry chemical extinguishers work well—keep them nearby. Keep written procedures on hand, walk through them with new hires, and test alarms often. Training sessions may feel tedious, but after an alert triggers in the early morning, you want clear heads, not panic.

Storage Strategies

Steel drums with sealed, vapor-tight caps cut down the chances of evaporation. Place containers far from oxidizers—mixing accidents can turn disastrous in seconds. Signs marking flammable storage must be visible and legible. If the facility uses a sprinkler system, double check that its spray doesn’t cause the chemical’s vapors to spread instead of suppressing them.

Handling Spills and Exposures

Spills test any safety culture. Absorbent pads, neutralizing agents, and spill kits are your best friends in a crunch. Have written instructions right next to cleanup gear—don’t count on anyone’s memory when nerves are frayed. Immediate area evacuation makes more sense than trying to contain fumes without backup support. I once saw slow action during a minor spill lead to hours of ventilation downtime and irritated airways for two staffers.

If exposure happens, quick response trumps hesitation. Flush skin or eyes at the nearest station, and always encourage prompt medical evaluation, even for exposure that seems minor at first. Documentation of incidents allows for process improvements, and honest debriefs make the next close call less likely.

Building a Real Safety Culture

Constant awareness, clear protocols, and regular hands-on training top any equipment list. It’s easy to fall back on old habits or assume everyone will “just know” what to do, but real adherence saves bodies, time, and money. Isobutyraldehyde won’t care if rules are bent or steps skipped. Strong communication—between shifts, departments, and management—makes a difference. Safety isn’t about fear, but respect for the risks and tools to face them head-on.

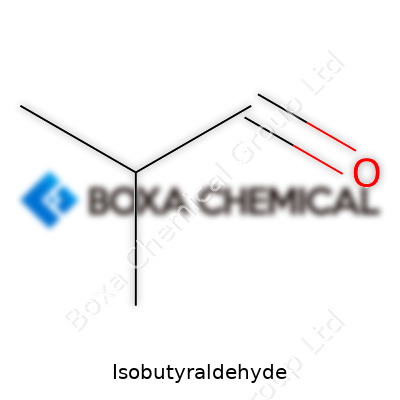

Isobutyraldehyde’s Formula and Why It Matters

Isobutyraldehyde stands out in the world of industrial chemistry because of a simple arrangement of carbon, hydrogen, and oxygen atoms. Its chemical formula is C4H8O. In plain terms, this compound shrugs off the complexity found in bigger molecules and offers something that chemists love: straight answers. You can trace its structure to four carbon atoms lined up to form a branching chain, with one of those carbons forming a double bond with oxygen at the tip, marking it as an aldehyde.

High school chemistry teachers use isobutyraldehyde as an example of functional groups. Chemists in the lab might recognize its sharp, pungent odor right away. The formula tells you everything you need for calculations, predicting behavior in reactions, or understanding how the molecule will connect with others. You won’t find any hidden extras lurking behind the formula — it’s straightforward.

Why Accuracy with the Formula Counts

Getting the formula right isn’t just academic nitpicking. A small error shifts you from isobutyraldehyde to another compound altogether. Isobutyraldehyde’s formula, C4H8O, translates to 2-methylpropanal in the IUPAC system, fixing its identity for chemists around the world. In my years in research, seeing two people talk about the same molecule with different names happens all the time. The formula cuts through that confusion.

People who work in large-volume manufacturing, where isobutyraldehyde is made by hydroformylation of propylene, depend on that accuracy. The right formula lets chemical engineers tune their reactors and helps supply chain folks plan raw materials. Tinkering with anything less precise invites accidents or costly mistakes.

Impact on Everyday Life

It hardly gets talked about outside the industry, but isobutyraldehyde influences daily routines more than most realize. Much of it ends up as isobutanol, a building block in paint thinners, plastics, and even synthetic flavors. The right formula is essential for engineers and scientists keeping water treatment facilities running, developing new biodegradable plastics, and scaling up flavor production for food companies.

Misreading the formula or using the wrong isomer — say, n-butyraldehyde instead of isobutyraldehyde — means you get entirely different properties, which can kill a project before it starts. I once saw a team in an R&D lab scrap a week of work after a mislabeling mix-up. Isobutyraldehyde, with its unique compact structure, leaves no room for error if your goal is consistent results.

Safer Handling and a Greener Tomorrow

C4H8O isn’t just shorthand — it signals the need for careful handling. Isobutyraldehyde is volatile and flammable. Companies that pay attention to the formula plan ventilation needs and responses to spills or leaks. Responsible handling protects workers and communities.

Looking ahead, pushing for greener production methods gets its start with a clear understanding of formulas. Efforts to cut emissions or find catalysts that turn propylene and syngas into isobutyraldehyde with lower energy input all rest on that solid chemical foundation. Researchers taking inspiration from nature’s own catalysts (enzymes) might stumble if there’s any confusion over ingredients.

Concluding Thoughts

Isobutyraldehyde doesn’t show up in the headlines, but its chemical formula, C4H8O, proves that even a small molecule can make a big impact. Understanding and respecting those few letters and numbers keeps labs safe, products reliable, and science on track. For me, that simple formula stands as a reminder of the value in getting the details right, every single time.

A Closer Look at a Common Chemical

Isobutyraldehyde usually flies under the radar. It’s a colorless liquid that finds its way into the production of plastics, resins, and even flavors and fragrances. I’ve spent years handling chemicals in a lab and on factory floors, and one thing’s clear—this one demands real respect. Breathing in its vapors or letting it spill can cause headaches, irritation, or worse. Nothing wakes you up quite like the sharp, pungent smell hitting you in the face when someone pops open a container without the right precautions.

Why Proper Storage Means Safety

The short-chain aldehydes like isobutyraldehyde can catch fire just as easily as lighter fluid. Leave a drum open near a heat source, or skimp on regular checks, and you’re running a real risk. I’ve seen some workers underestimate how fast vapors can build up in storage rooms—not a mistake anyone makes twice. The U.S. National Fire Protection Association classifies it as a Class IB flammable liquid, so even sparking a light switch in the wrong spot could end in disaster.

Isobutyraldehyde also reacts with oxygen over time, forming peroxides that crank up the explosion risk. Even a “minor” leak can mean major trouble if the vapors find an unintended ignition source. Safety experts recommend storing it at cool, well-ventilated indoor locations, away from sunlight, heat, or any potential sparks.

Storage Done Right: Location and Materials Matter

I always tell new techs: treat the storage area like a fortress and only the trained should enter. Businesses keep their stocks in cabinets that are fire-rated and grounded, lined with spill containment pallets. That way if a container gets knocked over, the liquid doesn’t seep under the floor or into drains. Ventilation isn’t just a box to tick; it’s the difference between a routine day and an ER visit. Forced-air extraction pulls fumes away before they can ever concentrate.

Original drums and containers always get checked for corrosion and tight seals. I once watched a delivery go south because some genius tried to repackage into plastic. The solvent ate through in a matter of days. Steel drums with proper labeling solve the issue of mystery leaks and confusion about what’s inside. It’s not just about keeping regulators happy—nobody wants to gamble with their lungs or the company’s insurance premiums.

How People Make It Work—And Make It Safer

Routine helps more than any buzzer or sensor. Good storage records mean the old stock rotates out, and new batches don’t get shoved behind and forgotten. For locations handling lots of isobutyraldehyde, workers run regular spill drills. Fast action, like plugging leaks with absorbent socks and ventilating the area, can turn a near-miss into a teachable moment.

Access control keeps the untrained out, and maintenance logs keep tabs on containers before they get brittle. Managers double-check that fire suppression systems are ready, often using foam or CO2 extinguishers that don’t just spray water. Emergency showers and eyewash stations ring the room, since the stuff burns like acid if it lands on skin.

Looking Ahead: Safer, Smarter Storage

It doesn’t matter if you run a small flavor lab or a sprawling chemical plant. The habits you build with isobutyraldehyde—constant vigilance, honest training, and reliable gear—make the difference. Equipment costs still beat cleanup costs every time. With tight procedures and a bit of respect for the chemistry involved, storage can stay routine, and risks remain manageable.

Understanding Isobutyraldehyde

Isobutyraldehyde pops up in quite a few places—factories, labs, everything from pharmaceuticals to coatings. I’ve seen it on shipping manifests, and let’s be clear—it’s not a household staple, and it rarely grabs headlines compared to chemicals like benzene or ammonia. Still, for folks working with it, or living near plants that use it, isobutyraldehyde is more than an academic concern.

Health Hazards on the Job

Exposure to isobutyraldehyde in closed or poorly ventilated spaces brings on watery eyes, headaches, and a dry, scratchy feeling in the throat. At higher levels, dizziness and light-headedness can follow. Most folks don’t spend their days around pure isobutyraldehyde, but production workers definitely get closer to it than they’d like. It’s also flammable, and anyone who’s been on a site that’s had a fire knows these kinds of chemicals ramp up the stakes.

The best evidence points towards irritation being the main short-term problem. There isn’t much research showing long-term effects from ordinary exposure levels. Still, a person with asthma or lung issues isn’t going to have a good day if a leak sends isobutyraldehyde into the air. The U.S. National Institute for Occupational Safety and Health suggests keeping workplace levels under 25 ppm for an average shift. Above that, safety goggles, gloves, and strong ventilation aren’t optional—they’re the only thing standing between exposure and a trip to the doctor.

Environmental Concerns

Isobutyraldehyde doesn’t hang around forever in the open air. Sunlight and water break it down over hours or days. That’s a silver lining, especially compared to heavy metals or PCBs that linger in soil and water for decades. Still, any spill or big release means a burst of smog-producing chemicals, because isobutyraldehyde reacts with other pollutants to create ground-level ozone. Anyone who’s lived through a high ozone alert, with warnings to keep kids indoors, knows this isn’t just theoretical. Ozone triggers asthma, makes eyes water, and reduces lung function—even after a short walk.

Big rivers or lakes probably won’t see massive fish die-offs from a single dump, but aquatic life suffers if enough of this chemical makes it into waterways. I’ve read fish exposed to strong concentrations get lethargic or die, especially in warmer weather. That stress trickles through the food chain and eventually hits people—whether they fish those waters or drink from them.

Responsible Management and Possible Solutions

Handling chemicals like isobutyraldehyde comes down to practical controls and clear rules. Regular leak checks, reliable personal protective equipment, and air monitoring in plants make a huge difference. Better training for workers and real-time alarms for gas leaks help spot trouble before it gets out of hand. When producers invest in closed systems—pipes and tanks that keep fumes contained—they reduce risk for neighbors and the planet.

Stricter reporting means communities get the facts about what’s in their air. It also challenges companies to rethink how much chemical they use. Blending environmentally safer additives into formulas, updating old equipment, and supporting real-time data sharing aren’t flashy steps, but they mean the air stays clearer and people stay healthier. I’ve seen firsthand that informed workers, engaged communities, and transparent companies are the safest mix. For a chemical that doesn’t grab much attention, isobutyraldehyde deserves a spot in conversations about health and safety.