Diethylene Glycol: A Commentary on Its Role, Risks, and Future

Historical Development

A look back at diethylene glycol’s roots tells a story of how industry responded to growing demand for low-cost, adaptable solvents. Synthesized first during the rise of large-scale petrochemicals in the late nineteenth century, producers soon recognized its unique capacities in the wake of World War I, as manufacturing and chemical engineering leapt forward. By the middle of the twentieth century, industries relied on this colorless, syrupy liquid for a range of tasks, from producing resins and plastics to acting as a softening agent for tobacco and paper. Demand surged with new plastics and coatings, and manufacturers held fast to diethylene glycol for its solvency and compatibility, not pausing long enough to weigh all risks—but later decades pushed change as tragic poisoning cases sharpened public focus on safety and oversight.

Product Overview

Diethylene glycol steps out as a clear, nearly odorless liquid. Manufacturers use it as a solvent, humectant, and intermediate in countless applications, especially where flexibility and stable performance matter. A staple in antifreeze, inks, adhesives, and textile conditioning, it plays a crucial supporting role in these industries, replacing higher-cost or less stable alternatives where budgets or chemistry require. Cheaper and more versatile than many peers, it drives down costs and supports modern convenience, but its reactivity and toxicity warrant real caution in handling and storage. In practice, diethylene glycol operates behind the scenes in formulations—rarely visible to consumers, but integral in keeping materials blendable, moisture-balanced, and workable.

Physical & Chemical Properties

In daily chemical work, understanding physical properties builds real trust in how and where to use diethylene glycol. It brings in a boiling point of 245°C, with a melting point at about minus 10°C, giving it liquid stability across varied temperatures. Miscible with water, alcohols, and several organic solvents, it dissolves many substances that otherwise clump or resist blending. This thick, viscous liquid brings a sweetish taste—deceptively similar to harmless substances, which has proved deadly in contaminated foods and medicines. Its moderate volatility and low vapor pressure mean it lingers rather than evaporates, making it useful in humidification and plasticization jobs. Chemical handling instructors stress head-to-toe protective measures not out of empty caution but hard-won lessons from accidental exposures.

Technical Specifications & Labeling

Buying or distributing chemicals today means close attention to technical specifications and proper labeling, not just because regulations demand it, but because missed details can prompt a public health crisis. Modern labeling requires unique product name, purity percentage, batch number, hazard pictograms, and contact information for reporting spills or exposures. Suppliers back up product lots with safety data sheets describing fire risks, incompatibilities, and first aid measures in plain terms, with bilingual or multilingual instructions for international buyers. Years ago, labeling rarely went beyond a name or simple hazard symbol; fatalities worldwide led to mandatory upgrades, making every drum and container a direct communication tool for safe use and responsible disposal. A lesson from the Elixir Sulfanilamide disaster in the 1930s echoes: clarity in chemical communication saves lives, not simply legal headaches.

Preparation Method

Manufacturers produce diethylene glycol by partial hydrolysis of ethylene oxide in water, usually under high pressure and moderate heat. This reaction briskly generates a mixture of glycols—mono-, di-, tri-, and beyond—then distillation or fractional crystallization divides out the sought product, based on different boiling points. Efficiency depends on reactor design, precise control of reactant ratios, and heat management, with modern plants using computer-guided automation where operators once handled valves and gauges by hand. Despite automation, plant workers keep a wary eye on reaction kinetics, as runaway heat or contamination can cause dangerous by-products. Tight control over production parameters bolsters both product quality and workplace safety, drawing on many hard-learned engineering lessons from past plant incidents.

Chemical Reactions & Modifications

Chemists in research and industry value diethylene glycol not only as a solvent but also as a core reactant. Its two primary hydroxyl groups provide a springboard for etherification, esterification, and polymerization, delivering polyurethane resins, flexible foams, and plasticizers. Manufacturers modify it through oxidation to produce glycolic acid derivatives or react it with acids and isocyanates to push deeper into material science. These reactions, if managed poorly, generate heat, pressure, and sometimes toxic by-products, driving home why chemical process safety sits front and center in lab and factory protocols. Technicians and engineers work together to ensure clean conversions not just to boost yield, but to minimize hazards both inside and outside the plant walls.

Synonyms & Product Names

Diethylene glycol appears under many aliases: DEG, 2,2'-oxydiethanol, diglycol, dihydroxyethyl ether. Product catalogs worldwide use these names interchangeably, but also attach branded names or regulatory codes, depending on market and region. Context matters. Laboratories, factories, and transporters make a habit of double-checking all labels and shipping documents, following experience with language barriers and abbreviation mix-ups that have triggered accidental product substitutions or customs delays. Clear traceability for every container, regardless of synonym or trade name, remains vital in keeping accidents and legal snags to a minimum.

Safety & Operational Standards

The chronic and acute health threats posed by diethylene glycol demand ironclad safety culture. Even small ingestions cause fatal metabolite buildup, with kidney and nervous system damage striking hardest. Plant protocols demand gloves, splash goggles, ventilation, and rigorous leak containment. Emergency showers and spill kits stand ready in storage corridors. OSHA and comparable global agencies require exposure limits, clear signage, and hazard communication training for any worker. Containers need secure secondary containment and regular inspection. Transport brings extra scrutiny—thorough documentation at every node, trained drivers, and emergency response plans are the norm. A culture of “just good enough” has no place where a single slip can provoke disaster, especially in pharmaceutical or food-adjacent sectors.

Application Area

Manufacturers use diethylene glycol in products ranging from unsaturated polyester resins and flexible foams to brake fluid, lubricants, and paints. Textile processors count on it for conditioning fibers, while ink and adhesive plants depend on its solvency and moisture management. In refrigeration and heating, it stabilizes freezing points. These uses drive home one fact: everyday modern convenience leans on substances most never see. Still, the same properties that boost industry have led to contamination incidents in medicine and food, showing the razor-thin margin for error in handling, labeling, and cross-industry supply chains. Unwavering vigilance by both regulators and users remains the linchpin for safe application.

Research & Development

A wave of innovation ripples through chemical engineering labs, searching for replacements with lower toxicity and stronger biodegradability. Green chemistry pushes for safer alternatives, but also explores process tweaks that trim energy costs and waste output. Ongoing studies track diethylene glycol’s behavior in advanced composites, nanomaterials, and rechargeable battery tech, hoping to crack new application markets while offsetting toxicity drawbacks. Government and industry researchers collaborate to refine detection of trace residues in foods, cosmetics, and pharmaceuticals, aiming to shorten response time between contamination and public notification. This shapes a more transparent, responsive market—one better aligned with public health without stifling innovation.

Toxicity Research

Medical literature catalogs chilling reminders of what happens when DEG enters the wrong products. Fatalities from cough syrups in Haiti, India, and Panama along with earlier poisoning outbreaks in the United States explain modern skepticism and regulatory vigilance. Toxicologists trace damage to metabolites that shut down renal function and cause multi-organ failure. Long-term studies measure occupational exposure, tracking cumulative effects and setting strict ceiling limits, while public health agencies reinforce bans on DEG in foods and pharmaceuticals. New research highlights the challenges of identifying substitutes—many alternatives cost more or lack the desired functional mix—keeping industry on its toes to balance performance, price, and safety.

Future Prospects

The future of diethylene glycol depends on both innovation and prudence. Industries still need a dependable, affordable glycol for resins, inks, and heat transfer fluid, but the call for consumer safety only grows louder. Investment dollars flow to technologies that can detect, neutralize, or wholly replace DEG in critical applications, from pharmaceuticals to plastics. Engineers explore advanced recycling and degradation pathways that could curb environmental buildup. Regulatory agencies monitor the global supply chain harder than ever, crossing borders and languages to catch emerging risks before they spill into public spaces. Industry’s responsibility sits not just in improved products, but in open communication and transparent supply chains, so the mistakes of yesterday do not return in new forms tomorrow.

Diethylene Glycol in Industry and Manufacturing

Diethylene glycol, often called DEG, shows up in more places than most of us realize. It acts as a solvent, which means it helps dissolve solid or liquid substances during production. Thanks to its effectiveness and low price, DEG works well in making plastics, polyester resins, and even certain dyes that color our everyday fabrics. Labs and factories rely on its ability to hold things together or keep mixtures stable while they're being processed.

Role in Cooling and Hydration

You can find diethylene glycol in coolants and antifreeze solutions. Car engines, industrial machines, and power stations all need cooling fluids that draw away heat, especially in summer. DEG helps regulate temperature and keeps engines running smoothly. Having worked at a car workshop for a few years, I saw firsthand how essential safe coolants are for vehicle maintenance, and how even small amounts of DEG made antifreeze work in freezing winters and burning summers.

Use in the Pharmaceutical World

Manufacturers sometimes use DEG to make lubricants for machinery that produces medicines or personal care products. It's important to note the difference between safe industrial purposes and potential risk. History teaches us hard lessons—misuse of DEG in medicine has led to disasters. For instance, a series of poisoning events in the early half of the 20th century, resulting from contaminated cough medicines, spurred stricter global drug safety laws. This shows that sometimes, a cheap industrial chemical's misuse in pharmaceuticals can be tragic.

Practical Experience from Consumer Products

As someone who has worked with cleaning manufacturers, I've seen DEG in products like wallpaper strippers, air fresheners, and some cleaners. When used the right way and kept out of reach from kids, these everyday items do their job without much worry. The trouble comes when regulations aren't followed or labeling gets ignored, which can lead to dangerous exposures. Even small amounts of DEG can be harmful if swallowed, so it's crucial that companies train their staff and inform customers about safety.

Environmental and Health Concerns

Diethylene glycol is toxic. Spills or accidents can cause poisoning, and it can seep into soil or water if companies neglect waste management. In the news, cases have cropped up where fake or illegally produced spirits contained DEG, putting lives at risk. Health officials argue for better enforcement and international cooperation to stop these harmful practices.

Pushing for Safer Solutions

Alternatives exist, but switching to safer chemicals takes investment and commitment. Some manufacturers have started using safer glycols or biodegradable solvents as regulators tighten rules. Community education, a transparent supply chain, and public safety monitoring all need attention. As a parent, I look for reputable brands and clear labels, because personal experience has taught me that quality and safety ought to go hand in hand. Government agencies and the private sector have to work together, investing in research and putting clear warnings on packaging—so consumers understand what they're buying and how to stay safe.

What Is Diethylene Glycol?

Diethylene glycol, or DEG, pops up in all sorts of industrial products: brake fluids, lubricants, paint, and even some cosmetics. It’s a colorless, syrupy liquid that mixes well with water and alcohol. It’s not found naturally and gets made mostly for use in manufacturing processes, not for direct use by people. You might spot it on ingredient lists or safety labels if you work around factories or shipping docks.

What’s the Risk?

Let’s talk straight: DEG is highly toxic to humans. Swallowing even a small amount brings severe health problems and, in a lot of sad cases, has proven fatal. Studies and medical reports paint a clear picture—exposure leads to kidney failure, nervous system damage, and in extreme cases, death. This is not something to brush off. Ingestion isn’t the only risk. Skin contact and inhaling the vapors can also trigger poisoning, although these routes don’t compare to the danger of swallowing it.

Real-World Disasters

History keeps receipts. In the 1930s, the United States dealt with a tragedy known as the “Elixir Sulfanilamide Disaster.” Manufacturers used DEG as a cheap solvent in a new medicine. Over a hundred people, many of them children, died of kidney failure. More recently, several cough syrup tragedies in places like Nigeria, Bangladesh, and Panama linked deaths to DEG contamination. Dozens lost their lives because companies cut corners or failed basic safety checks.

Why Do These Accidents Happen?

Profit and carelessness play a big role. Some companies go with DEG because it's cheaper than safe alternatives like glycerin. Others trust mislabeled or contaminated shipments. A lack of tough oversight lets these mistakes slip into the market, sometimes reaching products made for kids and sick people. In countries with underfunded regulatory agencies, tracking and testing for toxic chemicals doesn’t always happen. That leaves the door open for serious harm.

What Can We Do About It?

I’ve worked around supply chains long enough to know cutting corners is a recipe for disaster. For me, this topic underscores how important accountability and traceability are. Ingredient suppliers need transparency—every batch, every step. Companies should insist on rigorous lab testing, with independent labs checking purity before chemicals enter the supply line.

Stronger government oversight makes a difference too. Regular spot checks and surprise audits catch mistakes before they spread. Public reporting builds trust. Even simple barcode tracking systems help; knowing exactly where and when a batch of chemical gets produced limits the chance for fraud or mislabeling. Anyone making medicine, food, or cosmetics needs up-to-date training and real consequences for sloppy practices.

Consumers can stay informed by looking for certifications and buying only from reputable brands. But the biggest tool will always be prevention at the producer level. Industry and government working hand-in-hand, swapping information about recalls and accidents, always helps keep the worst disasters at bay.

The Big Picture

The facts on DEG are settled. Exposure brings real, measurable harm. The history of poisonings shows why everyone—from regulators to companies to consumers—carries responsibility. Constant vigilance, tough regulations, and open communication are not just smart or ethical moves; they save lives. DEG’s risks are clear. It has no business anywhere near products that go in or on the body.

Understanding the Risks

Diethylene glycol shows up in a lot more places than most people think. It finds its way into antifreeze, brake fluids, dyes, and even some household cleaners. Trouble comes when someone treats it like other chemicals found under the sink. Folks have mistaken diethylene glycol for safer cousins, but it causes kidney damage, nervous system breakdowns, and sometimes death. Keeping safety in mind while handling this stuff is not just good sense—it's a lifesaver.

Personal Experience with Chemical Safety

Over the years, I spent time in a factory where we used diethylene glycol. Early on, a co-worker trusted his worn-out gloves, thinking a quick splash during mixing wouldn’t matter. He landed in the hospital with nerve pain that wouldn’t quit. The lesson sunk in: basic gear makes all the difference. Even seasoned pros sometimes get too comfortable, but this isn’t the sort of chemical that lets you off easy.

Essential Safety Steps

Rubber gloves are just a start. Always wear eye protection and a lab coat or coveralls that fit well. Regular clothes soak up spills, and nobody wants diethylene glycol touching their skin for even a second. Goggles or a full face shield work best. I only realized the importance of face protection after a friend lost vision in one eye during a small splash incident.

Good ventilation isn’t optional. Fans or extraction systems help keep fumes from building up. The vapors can fry your nose and mouth, and breathing problems follow if the space feels stuffy. Never pour or mix this chemical without knowing if your workspace clears fumes quickly.

Every workbench using diethylene glycol should keep eye-wash stations and emergency showers within a fast walk. It’s easy to believe an accident won’t happen, until it does. Cleaning up after a splash works faster with clean water than any kit or chemical wipe, so fresh water on hand carries real weight.

Storage and Labeling

Always keep this chemical in sealed, labeled containers — never in anything people might reuse for food or drinks. I’ve seen people stick diethylene glycol in old water bottles “just for now.” That’s dangerous; mix-ups have caused tragic poisonings before. Labels should use bold letters and hazard warnings that nobody can miss.

Store diethylene glycol away from acids, bases, and oxidizers. Mixing it with other chemicals by accident, even in small amounts, turns a bad workday into a medical emergency. Secure storage means locking cabinets or rooms, with only trained people holding the keys.

Training, Communication, and Emergency Planning

Training saves lives. Anyone handling diethylene glycol needs hands-on instruction before even unscrewing the lid. This covers how to use protective gear, set up ventilation, and deal with spills. Regular safety drills remind everyone what to do if things go bad.

Supervisors must keep track of safety data sheets. Workers should know how to find these sheets in a hurry, since they hold answers about first aid, fire risk, and chemical reactions. Clear communication makes all the difference in busy workplaces; assumptions get people hurt.

Looking Ahead: Safer Practices

Some shops are swapping out diethylene glycol with less risky alternatives, whenever the job allows. Even if this chemical stays, more places run audits and install newer safety tech. No magic bullet makes chemicals safe by themselves, but daily care, proper gear, and a no-shortcuts mindset keep folks from harm. Every life counts, and in my experience, few shortcuts ever pay off.

The Risks of Underestimating Diethylene Glycol

Diethylene glycol often pops up in chemical warehouses and manufacturing floors. Years ago, I worked in a facility where the label on a barrel caught my eye. Most folks notice the warnings but push them to the back of their minds. The trouble is, this stuff has a dark history—every so often, news breaks about accidental poisonings, usually because someone thought storage was just a box to check off a list.

This chemical plays a role in making antifreeze, plastics, and even some pharmaceuticals. On paper, it looks manageable: a clear, odorless, syrupy liquid. Under the surface, it’s toxic. One sip is dangerous, and prolonged breathing of its vapors can wreck your health. The 1937 mass poisoning in the US is a harsh reminder; dozens died after using medicine mixed with diethylene glycol. That disaster gave us the FDA. Still, over 80 years later, the risk hasn’t vanished.

What Real Storage Looks Like

Leaving diethylene glycol in an unmarked drum or a poorly ventilated area isn’t just lazy—it’s a recipe for a catastrophe. Reliable storage always starts with clear, durable labels on every container. Staff with experience know: labels fade, and careless handwriting turns “diethylene glycol” into a smear. Insist on printed, chemical-resistant labels and check them regularly.

Storing this chemical in strong, sealed containers prevents leaks. A dented metal drum or flimsy plastic bin can spring a leak after one bump with a forklift. Stainless steel and special grades of plastic (like polyethylene) hold up over time and don’t react with the contents. Double-check gaskets and spouts before accepting a new delivery. Small holes become sprawling puddles—ask anyone who’s cleaned up a spill.

I once visited a facility where the staff kept diethylene glycol outside, exposed to the Texas summer. Heat speeds up evaporation, and those fumes creep through open windows and doors. Keep it in a cool, shaded, and well-ventilated room. Flammable storage rooms with exhaust systems keep vapors from pooling. Even if nobody smokes nearby, static or a stray spark can trigger trouble.

Training and Emergency Plans Save Lives

Never assume everyone instinctively knows what to do around dangerous chemicals. All staff—maintenance, janitorial, new temp hires—should learn safe handling. Simple rules like wearing gloves and eye protection need regular reminders. Some know-it-alls treat this as a formality, but skin contact is all it takes for diethylene glycol to start doing its damage.

Emergency showers and eye-wash stations aren’t optional. These installations look expensive, but you never want to explain to a family that saving a few bucks took priority over their loved one’s safety. Spill kits must remain close to the storage area. The best facilities keep drills fresh—not just a one-time show at orientation. Someone’s quick thinking during a leak will always matter more than the latest safety poster.

Fixing Weak Links in the Chain

Inspect every storage space on a schedule. I’ve seen blocked vents, expired personal protection gear, even food stored close to chemical barrels. That’s an accident waiting to happen. Assign a specific person to check these things, and rotate people to keep everyone sharp.

Look for organizations sharing best practices. The American Chemical Society, OSHA, and Health and Safety Executive all publish free guides. Build a system around these standards, and don’t settle for “good enough.” Review accident reports from other companies and learn from their mistakes. There’s no excuse for cutting corners. For something as hazardous as diethylene glycol, safety demands commitment every single day.

What Stands Out About Diethylene Glycol

Diethylene glycol, often found in products ranging from antifreeze to certain manufacturing processes, draws attention because of its clear, almost water-like appearance. It doesn’t carry that strong odor many chemicals have and feels a bit slick or oily to the touch, which signals right away that it’s not your everyday kind of liquid. With its sweetish taste—something that’s gotten people into trouble in the past—it mixes well with water, alcohol, and many other solvents. You’ll see it popping up all over the place in industry, especially as a solvent or intermediate.

Physical Properties You Notice Right Away

This liquid has a boiling point higher than what most folks expect—up at 245°C—so it doesn’t just evaporate in a hurry. Its freezing point sinks to about -10°C, so it stays liquid under a lot of tough conditions. If you’ve ever spilled some, you know it doesn’t evaporate fast, unlike something like ethanol or acetone.

Given its density, which sits just a notch above water at around 1.12 g/cm³, it flows easily but carries a little extra heft. It spreads across surfaces in a way that makes cleanup a job for gloves, not just a paper towel. That slipperiness hints at its use as a plasticizer or in applications where smoothness and flexibility count.

It’s hard not to remember its faint sweetness. People have mistaken it for safer substances before, and the health risks can’t be pushed aside. Even a small exposure through skin or inhalation doesn’t give off any stinging or burning, tricking some into thinking it’s harmless.

Chemical Characteristics That Matter

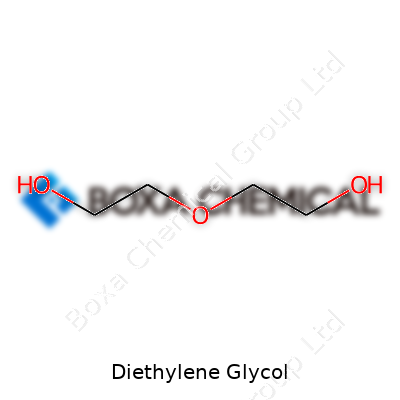

Diethylene glycol belongs to the glycol family, which means it’s a dialcohol—or diol, for those who love the details. The two hydroxyl groups on its molecule let it hook up with other chemicals or dissolve a wide range of substances. That’s why chemists like using it as a solvent in things like resins or dyes.

It doesn’t light on fire easily; you need the temperature to climb above 143°C before its vapors will catch a spark. On the scale of flammable risks, it stays on the lower end, but the vapors can still burn if mishandled. If you mix it with strong oxidizing chemicals, trouble starts—things can heat up or become reactive fast.

Its stability, when left on its own under regular storage conditions, makes it a favorite in long-term industrial uses. That stealthy stability can create a sense of safety around the chemical, which sometimes leads to corners getting cut with storage or labeling. Contamination can turn tragic, as history has shown in mass poisoning incidents worldwide.

Risks and the Way Forward

The sweet taste and easy blending fool people into underestimating the health risks. Swallowing even a bit of diethylene glycol, whether by accident or due to contaminated products, can damage organs and prove fatal. The infamous Panama cough syrup tragedy, where hundreds died after ingesting medicine tainted with this compound, still haunts public safety professionals.

Factories and labs across the globe rely on training, labeling, and strict oversight to keep workers and consumers protected. Simple things—like making sure every drum has a clear label and every worker knows that sweet taste spells danger—keep tragedies from repeating. Regulators also need active monitoring, not just rules on paper.

Moving forward, mix-ups between lookalike or sweet-tasting chemicals like diethylene glycol and safer substances can’t happen if education and real-world drills are standard. Adopting non-toxic alternatives where possible will keep both workers and end-users out of harm’s way. Every safe day on the production floor depends on knowing exactly what’s inside that tank and respecting what it can do—both good and bad.