Butanal: A Detailed Examination from Past to Future

Historical Development of Butanal

The story of butanal stretches back to the period when chemists first started breaking down heavy alcohols into smaller fragments. Early 20th century laboratories began isolating butanal—also called butyraldehyde—during experiments using fermentation and oxidation. The large-scale era for butanal started as industrialists realized its importance in the synthesis of plasticizers, solvents, and flavor agents. Once chemists improved processing by using the oxo process (hydroformylation of propene), butanal production exploded in both volume and diversity. This approach became the backbone of modern butanal production, firmly rooting it in the toolkit of the chemical industry.

Product Overview

Butanal stands as a colorless liquid with a sharp, pungent odor. Chemically, it's an aldehyde with four carbon atoms and the formula C4H8O. Versatility sets it apart: butanal acts as a building block to create compounds that touch all sorts of industries, including plastics, agrochemicals, and flavors. Many companies stock butanal as a basic raw material, offering it in various grades for lab or industrial use. Experience has shown that its low cost and reactivity allow companies to get more from every batch, making it a staple in both established and emerging markets.

Physical & Chemical Properties

Butanal's physical characteristics make it easily distinguishable on a bench. At room temperature, it stays liquid, with a boiling point near 75 °C and a melting point of about -99 °C. It dissolves in organic solvents and mixes only sparingly with water. Its vapors are heavier than air and can travel to ignition sources, raising fire hazards that demand strong chemical handling skills. As an aldehyde, butanal reacts with a range of nucleophiles, branching out into condensation reactions, reductions, and polymerizations. Few small molecules offer the same blend of volatility and reactivity, keeping it valuable for process chemists and formulators alike.

Technical Specifications & Labeling

Producers provide butanal measured for purity, water content, residual acids, and stabilizer presence. Commercial samples almost always include a stabilizer, such as hydroquinone, to keep oxidation and polymerization in check during storage and transit. Packaging involves tightly sealed steel drums or tanks with clear hazard labeling—flammable liquid, acute toxin inhalation, skin and eye irritant. Handling butanal in the lab means wearing gloves, goggles, and lab coats, given the irritancy and noxious odor. Safety data sheets from suppliers spell out these requirements in practical terms, leaving users with no ambiguities about the risks.

Preparation Method

Industrial players create butanal largely through the oxo process, taking advantage of the reaction where propene, hydrogen, and carbon monoxide combine in the presence of a cobalt or rhodium catalyst. This method works at moderate temperature and pressure, giving high yields that meet the world’s demand. In specialty labs, chemists sometimes prepare butanal by oxidizing n-butanol—a simpler route but one better suited for small amounts. Real industrial throughput comes only from the hydroformylation path, with engineering advances steadily improving energy efficiency and catalyst recovery.

Chemical Reactions & Modifications

Butanal sits at the center of many synthetic routes, and its reactivity feels almost limitless. You can reduce it to n-butanol, making a key intermediate for plasticizers and solvents. Through aldol condensation, butanal creates 2-ethylhexenal, a starting point on the way to 2-ethylhexanol—vital for producing phthalate plasticizers. Reacting butanal with amines forms imines, paving the way for pharmaceuticals and fine chemicals. Its ability to act as both electrophile and reactant gives chemists the creative leverage to build complex molecules for a range of applications.

Synonyms & Product Names

Butanal has rolled through history with a few different names. It crops up as butyraldehyde, n-butanal, or 1-butanal on purchase orders and research papers alike. Each label points to the same molecule, and all hint at its roots: butyric acid and aldehyde functionalities. Suppliers use these names interchangeably in catalogs, but they amount to the same practical chemical.

Safety & Operational Standards

Anyone working with butanal needs to respect its hazards. Its vapor catches fire at low concentrations, with a flash point around -7 °C. Inhalation and skin contact spark irritation, so strong ventilation, gloves, and splash goggles come into play every time someone cracks a drum. Storage rules call for cool, dry, and well-ventilated areas away from ignition sources. Most facilities implement spill controls—absorbent materials and containment strategies—since even modest leaks bring steep fire, toxicity, and odor risks.

Application Area

Butanal’s main markets span from plasticizer manufacture to pharmaceuticals. Key downstream chemicals such as 2-ethylhexanol, an ingredient in flexible PVC, rely on a steady supply. Agrochemical firms draw on butanal for synthesizing herbicides. Flavors and fragrance producers slip it into formulations to recreate buttery, nutty profiles. Coating manufacturers appreciate its solvency and reactivity when making resins. Research labs take advantage of its simplicity for testing organic reactions and kinetic studies. In nearly all these fields, butanal serves as both ingredient and testing ground for better, safer, or more effective products.

Research & Development

Research surrounding butanal happens on several fronts. Catalysis scientists constantly search for improved oxo reaction systems, coaxing higher yields or lower by-products. Analytical chemists push for faster, less wasteful purification steps and tighter impurity control. On the application side, R&D departments experiment with new plasticizers and resins based on butanal derivatives, targeting markets where existing options fall short. Many academics focus on the health impacts of exposure, modeling risks for workers and the public. These research efforts keep butanal chemistry relevant, no matter how far technology evolves.

Toxicity Research

Toxicologists keep a close watch on butanal’s effects. Short-term exposure leads to nose, eye, and skin irritation, while longer-term or higher exposures can cause nervous system symptoms and potential organ impact. Lab studies in animals show that butanal does not build up in the body but clears mostly through exhalation and urine, though high-dose tests warn of respiratory trouble and behavioral changes. Both OSHA and EU regulators cap occupational exposure limits, and industrial sites adopt these limits with careful air monitoring. Poisoning incidents remain rare, but the chemical’s reputation as a potent irritant means it gets managed with respect and vigilance.

Future Prospects

Demand for butanal will most likely keep rising as new uses for its derivatives emerge, especially in flexible plastics and coatings. Trends in green chemistry drive research toward renewable feedstocks and less energy-intensive production, so biomass-based butanal may arrive soon. Efforts to redesign industrial processes for lower emissions and waste give butanal manufacturing a shot at standing out as a cleaner, more sustainable part of the chemical supply chain. The push for better personal safety technology could also change best practices in storage and handling. As product designers and researchers turn to more sustainable materials, butanal’s versatility means innovation and safety will stay front and center in years to come.

How Everyday Life Runs on Butanal

Few people recognize butanal by name, but its fingerprints show up all over daily life. Household products, vehicles, even the air quality in cities—all see some impact from this simple molecule. Butanal belongs to a group called aldehydes, and it serves as a building block in manufacturing and industry. Over the years, work in a chemistry lab exposed me to butanal's distinctive pungent smell, but also revealed its importance far beyond the lab bench.

Key Uses That Shape Our Environment

Butanal acts as a major ingredient in producing plasticizers. These help keep plastics flexible, making them useful for wiring insulation, flooring materials, toys, and even medical equipment. Without these additives, many of these products would turn brittle and break apart. This flexibility extends the life of the products and cuts down on waste, which benefits both businesses and the environment. The push for more durable, safer materials continues to push chemists to refine butanal-based solutions.

The compound also plays a big role in making chemicals called butanols. Butanol finds a place in cleaning agents, paint removers, and printing inks. These applications matter to everyone: They keep surfaces sanitized, allow artists and construction professionals to do their jobs, and enable printing processes to work on a massive scale. Life simply gets more convenient when industrial processes run efficiently, and butanal sits behind much of that progress.

Blending Into Flavors and Fragrances

Oddly enough, butanal's sharp smell doesn't stop it from popping up in the flavor and fragrance world. In tightly controlled amounts, it helps create artificial flavors for food products and fragrances for personal care. Anyone who's ever tasted vanilla-flavored dessert or caught a whiff of a fruity shampoo has likely encountered a trace of butanal, shaped along the way by skilled formulators who know how to use it safely. The key is sticking to strict limits, as excess can quickly ruin a product or become hazardous.

Risks and the Need for Thoughtful Use

Butanal doesn't come without drawbacks. Spills or leaks in factories release fumes that irritate eyes and lungs. Workers exposed to high levels face real health concerns, so industry puts a heavy focus on ventilation, personal protective gear, and careful containment. Regulators around the world now demand better air filtration and safer work practices than ever before. These rules grew up for good reason—history shows what happens when safety falls short, from minor allergies to severe respiratory problems.

Room for Safer Alternatives and Greener Methods

Public concern grows as the volume of chemicals circulating through society rises. Producers face pressure to develop greener ways to make butanal and stronger, less polluting alternatives for plastics and additives. Some research now tackles creation from plant-based materials instead of petroleum, cutting down on harmful emissions. A big breakthrough in sustainable chemistry could soon shift the industry forward, protecting both human health and the world around us.

What Matters to Us

Understanding what butanal does grounds us in how much modern life depends on invisible players. Everyone expects durable materials, clean spaces, and safe food—without always thinking about the chemistry beneath the surface. Balancing these benefits with safety and environmental responsibility will decide how butanal shapes the future. Real progress comes from listening to researchers, regulators, and everyday users, and keeping our eyes open for ways to do more with less harm.

Why Butanal Needs Respect in the Workplace

Butanal shows up in several corners of manufacturing—solvents, flavors, even fuel components. Still, its flammability and vapor remind me of other chemicals people too often take for granted in a rush to get things done. One spill or careless whiff, and health takes a real hit. Inhaling butanal triggers throat and lung irritation, and its vapors carry an explosion risk. People sometimes forget: shortcuts on protective equipment or proper storage create accidents, not productivity.

Personal Protective Gear Makes a Difference

Simple gloves, goggles, and lab coats cut down the number of skin rashes and burns I’ve seen happen. Skin contact with butanal feels similar to holding a hot pepper: people regret it right away. Safety glasses need to fit well, since even a fraction of a drop stings eyes badly. Respirators come into play if the work area isn’t well-ventilated; nobody wants a coughing fit or dizziness halfway through a shift. Insisting on protection isn’t a paperwork drill—it’s just looking out for friends and coworkers.

Ventilation and No Open Flames—Basic or Bust

One of the real risks with butanal comes from vapors spreading out across a badly ventilated room, especially when someone lights a match or flips a switch that sparks. Explosions rarely look like movie scenes. Still, the aftermath stays with you much longer. Exhaust fans and hoods pull those hazards away before they build up, so I always walk through the shop before starting. Working outside or near a window may not cut it where volatility runs high.

Safe Storage Reduces Nightmares

I remember trying to track down the source of a distinct, acrid smell, only to discover a dented canister leaking in a forgotten corner. Metal containers with tight lids help keep butanal from escaping. Storing them away from acids or oxidizers keeps fires at bay. The rules aren’t there to slow work down. They help ensure staff get to leave every day without drama from mixing chemicals that never belonged together.

Handling Spills Quickly

Spills never give much warning, and mopping them up with a rag just spreads hazards. Absorbent materials, such as sand or commercial spill kits, do more than a paper towel ever could. Afterward, good practice calls for bagging it all up in sealed containers, so it doesn’t pose a threat to sanitation workers down the line. Reporting the incident, even a minor one, helps the team learn and react faster next time. People sometimes shrug off tiny leaks, but that attitude can lead to larger problems down the road.

Training and Preparedness

The only thing worse than facing a chemical you know nothing about is watching someone else panic in the heat of the moment. I’ve found that running drills—evacuation, spill response, first aid—toughens teams up for real-life issues. Training gives confidence to act fast and effectively when rules don’t seem so clear under pressure. Safety data sheets pinned up where everyone can see them make information more reachable than a binder buried in a drawer.

Looking After Each Other

Handling butanal need not become a horror story. Wearing proper gear, planning ahead, and keeping communication open cuts down on mistakes. Every workplace accident that doesn’t happen thanks to solid preparation means one less family facing an unexpected hospital visit. Real safety feels like a group effort—and butanal reminds us not to let our guard down.

What Is Butanal?

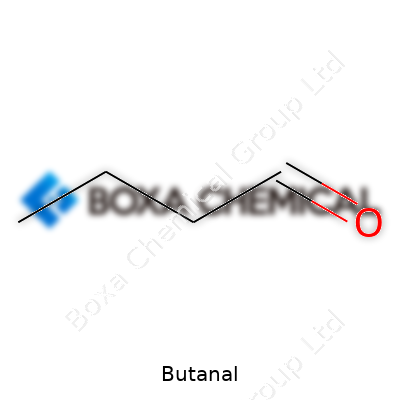

Butanal stands as a straightforward member of the aldehyde family. This molecule carries its own legacy in both industrial chemistry and organic labs. Every time I handled butanal in a teaching lab, I found it easy to spot by its sharp, pungent smell. This reminds you quickly: aldehydes are reactive. Butanal’s structure provides just the right mix of simplicity and functionality for people researching both chemical reactivity and practical applications.

The Formula Breakdown

The chemical formula for butanal is C4H8O. This formula marks out four carbon atoms, eight hydrogens, and a single oxygen. There’s no need to overthink how it’s put together. Drawing it out, you’ll see a straight chain of carbons, ending with the aldehyde group (-CHO). It’s this group that shapes many of butanal’s reactions and its place in chemical production.

Butanal in Everyday Life

Chemical names sometimes sound removed from daily living, but butanal finds its way into genuine, real-world uses. Factories rely on it mainly for making plasticizers, which keep plastics flexible. Pharmaceutical companies use butanal as a starting point for synthesizing more complex molecules. Fragrance and aroma chemists have long known that butanal’s scent is noticeable in certain food flavors and perfumes, though its strong smell means less is more in these settings.

Safety First

I always learned to handle aldehydes like butanal with care. The very properties that make them useful—such as easy reactivity—also mean they can irritate skin and lungs. Safety data sheets warn clearly about using gloves and working under proper ventilation. No one wants to discover through a coughing fit what it means to cut corners in the lab.

Environmental and Health Considerations

Butanal evaporates quickly at room temperature, which makes spills more of an inhalation problem than a slow-burn hazard. On a global level, volatile organic compounds (VOCs) like butanal play a role in air quality issues. Overexposure affects people working in chemical plants the most, but accidental releases can impact air near factories too. These health and environmental points underline why tight regulations and training matter in workplaces where butanal is used or produced.

Making Chemistry Work for Us

So, why fuss over a small molecule like butanal? Its formula, C4H8O, looks simple—honestly, it’s among the easier formulas I memorized in school. Yet its presence in plastics, medicines, and fragrances shows how small changes at the molecular level can produce big results in manufacturing and technology. Understanding the risks and benefits of butanal reflects well on any chemist or industry professional working with it.

Responsible Choices and Solutions

Safer handling starts with knowledge. Good training and strong safety cultures reduce risk. Regular monitoring lowers chemical leaks and misuse. Investing in improved ventilation, spill containment, and clear workplace labeling all lower the chance of harm. In research, green chemistry pushes for less hazardous alternatives that deliver the same commercial advantages with fewer side effects. Collaboration between chemists, regulators, and manufacturers keeps moving us closer to safer, smarter solutions involving chemicals like butanal.

The Risks Tied to Butanal

Workplaces that use butanal, often called butyraldehyde, handle a liquid that comes with a sharp odor and a reputation for being flammable. Breathing it in or touching it can irritate skin, lungs, and eyes. Anything this volatile catches fire fast; all it takes is a little static or a short spark. After years working near laboratories and storage facilities, I’ve learned people sometimes underestimate these hazards, especially after a few safe deliveries in a row. But one slip up means risking health and property.

Picking the Right Storage Container

Nobody should store butanal in generic, thin-walled jugs or containers that don’t close properly. Only containers built to handle flammable materials with tight, leak-proof seals make sense. Stainless steel and special glass containers with secure screw tops give far better protection than standard plastic. Strong, approved drums or safety cans built to survive a knock matter more than most think—especially since even a tiny leak puts everyone nearby at risk.

Temperature and Location Make a Difference

Butanal wants to evaporate. Keep storage cool and away from direct sunlight. Fire codes say to avoid heat sources, flames, and busy work areas. The ideal spot is a dedicated chemical cabinet, far from exits and not in any hallway traffic. The best cabinets are designed for flammable liquids, with self-closing doors and built-in containment for spills. Anyone who thinks a regular closet will do is taking chances.

Ventilation Isn’t Optional

Storing anywhere without strong vents lets fumes linger. Inhaling those fumes day after day leads to headaches and even lung problems, especially in small rooms. Airy spaces with working exhaust systems keep concentrations below danger limits. I have seen workers ignore warning signs about poor air until headaches and runny eyes became the norm. If you can smell the butanal, ventilation isn’t doing its job.

Labeling and Emergency Planning

Clear, permanent labels need to spell out what’s inside every storage drum. A simple tag saying “BUTANAL—FLAMMABLE, TOXIC” in large print cuts confusion and stops button-pushing newcomers from opening the wrong lid. Every site should train people on chemical spill cleanup and have spill kits ready—absorbent pads, neutralizers, heavy gloves, and eye wash bottles. Quick thinking matters, but real safety starts with practice before any accident happens.

Regulations: More Than Just Paperwork

The Occupational Safety and Health Administration (OSHA), along with fire marshals and insurance companies, check on butanal storage during site inspections. Following the rules guards against fines and keeps insurance valid. Even small shops running on a budget have to follow these standards. It isn’t red tape for the sake of it. These rules exist because fires and health scares have happened before, and ignoring history usually means repeating it.

Improving Butanal Storage

Placing safety ahead of short-cuts pays off over time. Investing in approved cabinets, reliable containers, and backup ventilation pays back every time an accident gets prevented. Staff training lowers the risk of panicked responses. It helps to bring in a professional for regular safety audits—fresh eyes catch what routine can make invisible. Safe storage keeps people healthy and companies running, which makes the effort worth it.

Butanal: More Than Just a Factory Chemical

Butanal, sometimes called butyraldehyde, pops up mostly in industrial settings. Workers in places that make plastics, rubber accelerators, or solvents might run into it more often than regular folks. It’s a clear, flammable liquid, and it carries a strong, sharp smell that makes you want to step back. I remember stepping inside an old rubber plant on a field trip—one whiff forced me back to the door. That’s the body’s way of telling you something isn’t right, and in the case of butanal, the warning makes sense.

What Happens When Butanal Gets Into the Body

Breathing in butanal throws your body for a loop. At low levels, you’ll probably get a headache or irritation in your nose and throat. Higher levels can bring coughing, dizziness, and even feelings of confusion. Eyes start watering. A coworker once told me about ending a shift with a sore nose and “burning eyes” after a ventilation fan broke down in a mixing room. The operators didn’t have masks on hand and toughed it out until the line stopped. This was not a unique story. Across North America, the National Institute for Occupational Safety and Health lists butanal as a hazardous air contaminant for a reason. Short-term exposure makes life miserable, but long-term exposure—especially in jobs that don’t rotate workers or keep the air fresh—raises the stakes.

Butanal absorbs through skin as well. If someone spills it or gets splashed, red, itchy patches can break out almost immediately. I once saw a chemical engineer scrub off his arms at a wash station for fifteen minutes straight, anxious about missing a spot. That might seem overboard, but even a brief lapse gives butanal a head start inside the body.

Long-Term Impact: More Than Annoyances

Research out of Europe ties repeated butanal exposure to nerve damage, kidney stress, and in rare cases, liver trouble. Some early animal studies hint at carcinogenic risks, but evidence in humans isn’t strong enough yet to label it a cancer agent. Still, the possibility alone should push workplaces to take stricter safety measures. Not all factories spring for local exhaust fans or distribute personal air monitors. Cost-cutting shows up first in maintenance budgets, and second in employee health complaints.

Simple Ways to Lower Risk

Protecting people boils down to three things: fresh air, good gear, and strong training. Modern ventilation makes a big difference. A shop foreman once walked me through his plant, proud of the new overhead extractors pulling fumes straight out. Everyone had fitted respirators and learned the emergency wash routine by heart. Case numbers for “chemical nose” dropped steeply. Personal protective equipment—gloves, aprons, goggles—sets up a barrier before you even feel a tingle. Culture matters, too. Routine reminders, visible safety data sheets, and a habit of reporting minor symptoms help catch problems before they turn into emergencies.

Folk wisdom sometimes lingers longer than science in old industries, but the evidence keeps stacking up. If a chemical like butanal burns your nose and steams your eyes, respect the signal. Smells, itches, and foggy thinking all matter. The best job perk isn't hazard pay; it's going home with clear lungs and steady hands.