How is Chloromethane stored and handled?

Operation precautions:

Strictly sealed, provide sufficient local exhaust and comprehensive ventilation. Operators must

undergo special training and strictly abide by the operating procedures. It is recommended that

operators wear filter gas masks (half masks), chemical safety goggles, breathable anti-virus

clothing, and chemical-resistant gloves. Keep away from fire and heat sources, and smoking is

strictly prohibited in the workplace. Use explosion-proof ventilation systems and equipment. Prevent

gas leakage into the workplace air. When transporting, load and unload lightly to prevent damage to

cylinders and accessories. Equipped with corresponding types and quantities of fire-fighting

equipment and leakage emergency treatment equipment.

Storage precautions:

Store in a cool, dry, well-ventilated warehouse. Keep away from fire and heat sources. Storage

temperature should not exceed 30 ℃. It should be kept away from oxidizer, do not store together.

Explosion-proof lighting and ventilation facilities are adopted. Prohibit the use of mechanical

equipment and tools that are prone to sparks.

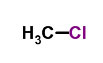

What is Chloromethane used for?

This product is used in the production of methyl chlorosilane, tetramethyl lead, methyl cellulose,

etc., a small amount is used in the production of quaternary ammonium compounds, pesticides, and is

used as a solvent in the production of isobutylene rubber.

This product is an important raw material for organic synthesis. Mainly used to produce

organosilicon compound - methyl chlorosilane, and methyl cellulose. It is also widely used as a

solvent, extractant, propellant, refrigerant, local anesthetic, methylation reagent, and used in the

production of pesticides, medicines, spices, etc. About 80% of the methyl chloride produced in the

world is used to produce methyl chlorosilane and tetramethyl lead, but since the antiknock compounds

in gasoline are gradually being replaced by unleaded substances, the consumption of tetramethyl lead

is gradually decreasing.